FROM THE FIRST IDEATO THE FINISHED PRODUCT

Kunststoff-Institut Luedenscheid GmbH (KIMW GmbH Luedenscheid) is your neutral partner for questions along the entire value chain. From the first idea to the finished component, we support you in the entirety of your processes. Or find the right partner for you from our network.

APPLICATION- &

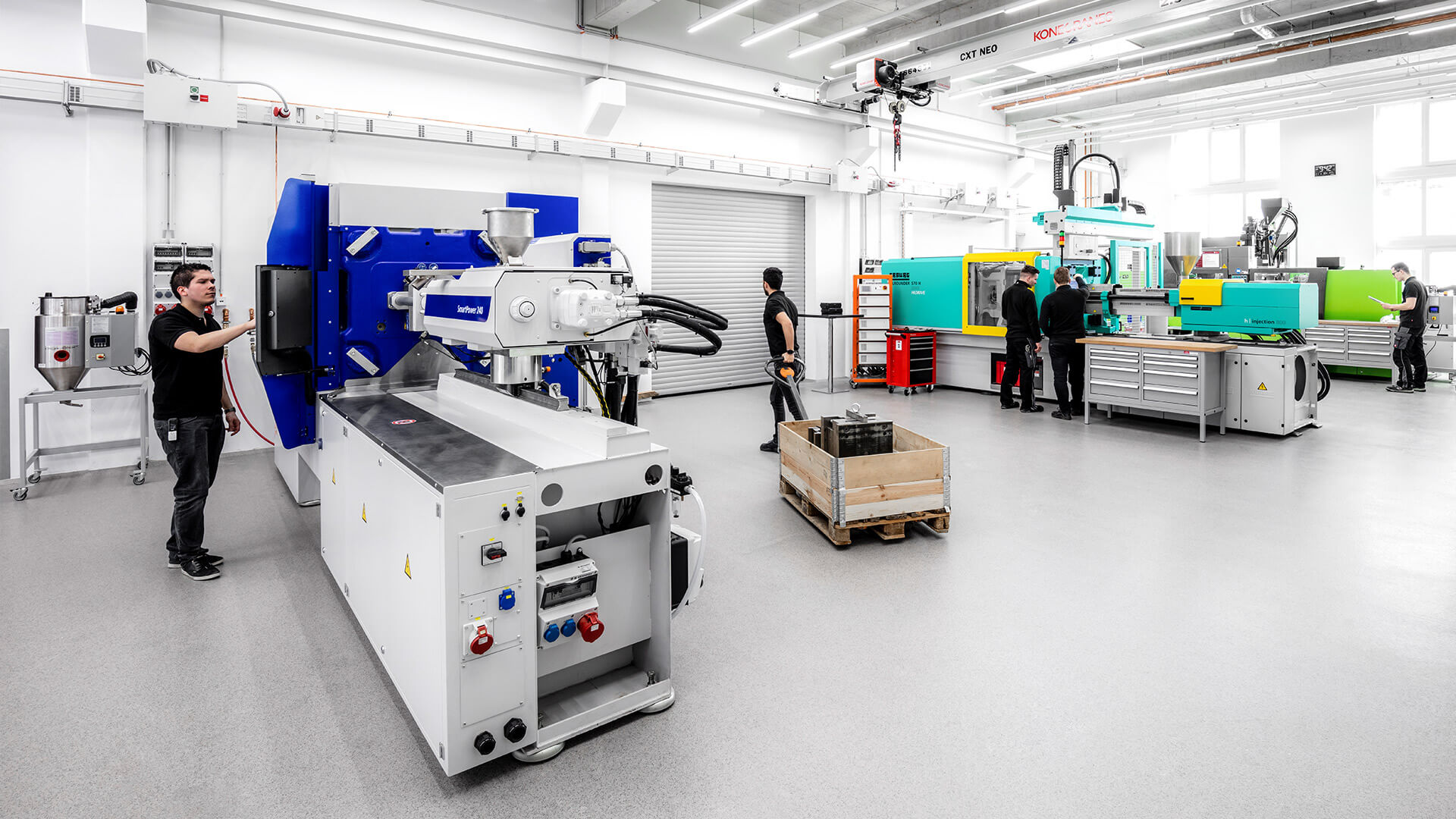

TOOL TECHNOLOGY

We offer process engineering support for sample and series processes, optimize existing production processes with you or integrate new application-oriented production processes into your operational sequence. We are also at your side from the design process to the optimal tool design to the check-up of your new or series tool.

SURFACE TECHNOLOGY

In addition to surface design, we support them in the selection, application and evaluation of an optimal treatment technique for molded parts and tools.

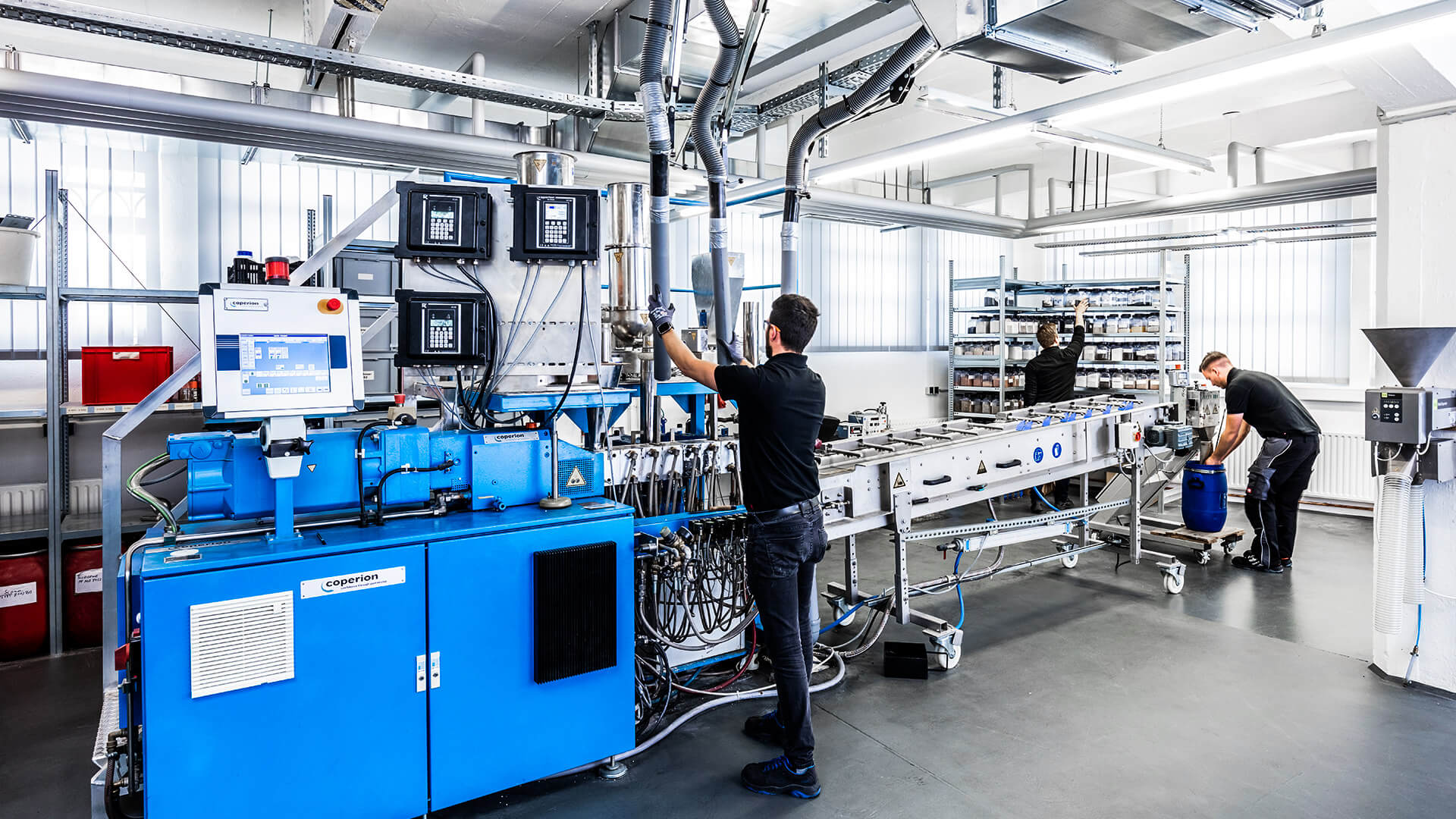

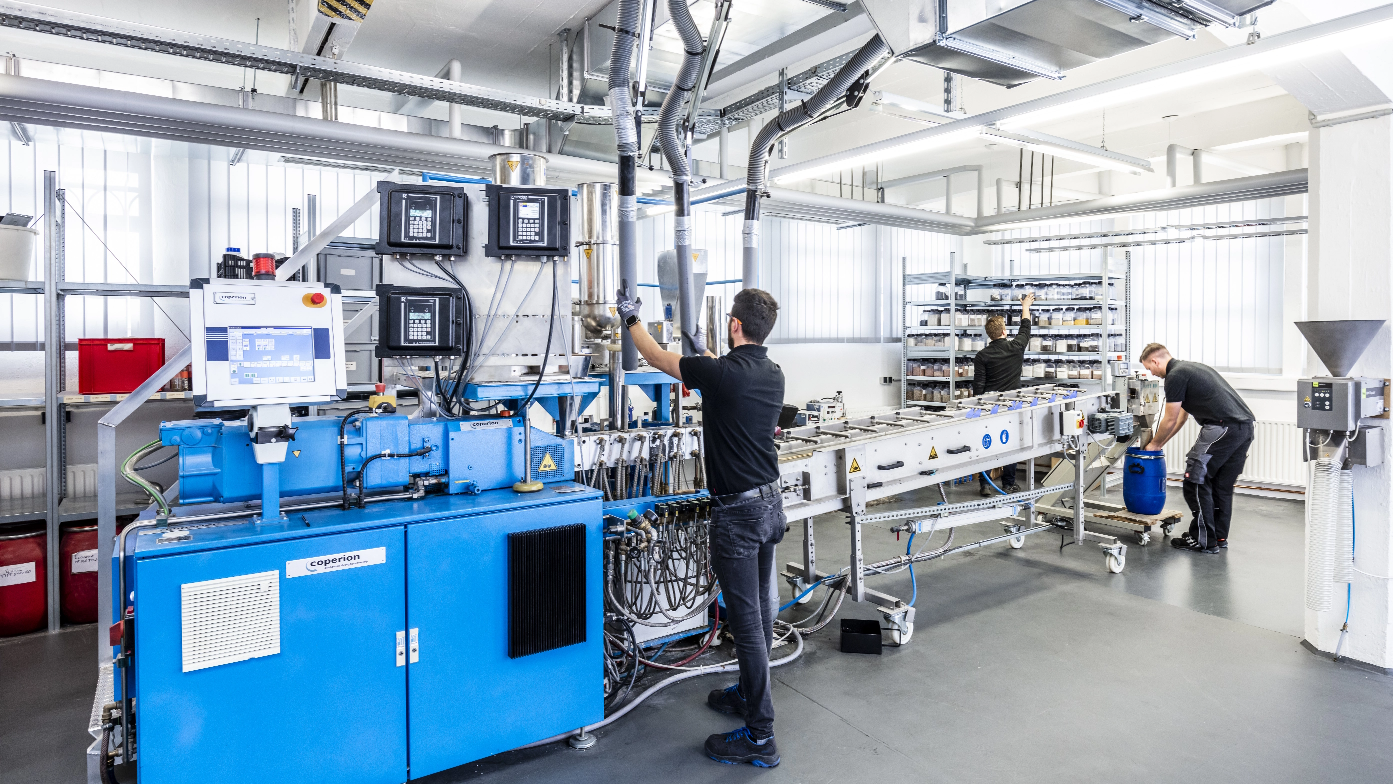

NEW MATERIALS

Selecting and deciding on the right material is part of a responsible task. Together with you, we develop practical solutions to this challenge. This includes the development of new materials as well as the selection of suitable alternative materials.

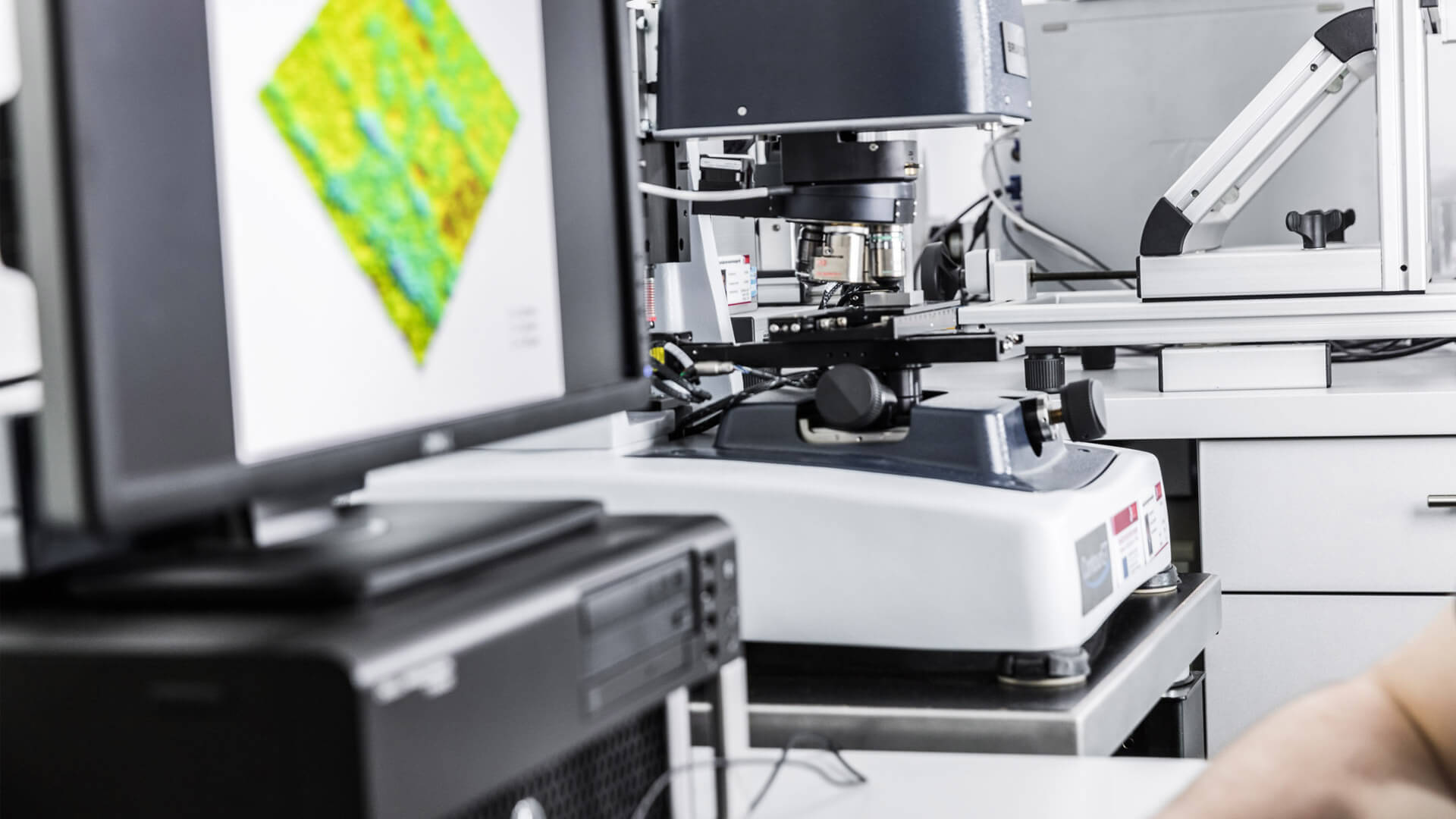

PROFICIENCY

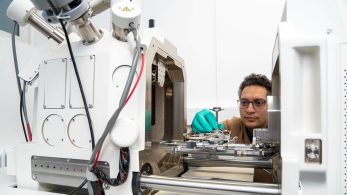

TESTING

Our suitability tests and reference materials cover a wide range of tests and analyses. The focus is on different plastic materials, products and processing.

PROCESS ENGINEERING

Together with you, we optimize existing production processes or integrate application-oriented new manufacturing processes into your operational procedures. We not only use our own state-of-the-art machinery, but also offer this service in-house.

SURFACE TECHNOLOGY

In addition to surface design, we support them in the selection, application and evaluation of an optimal treatment technique for molded parts and tools.

NEW MATERIALS

Choosing and deciding on the right material is part of a responsible task. Together with you, we develop practical solutions to this challenge. This includes the development of new materials as well as the selection of suitable alternative materials.

RING TESTS

Our proficiency tests and reference materials cover a wide range of tests and analyses. The focus is on different plastic materials, products and processing.

Current

Joint projects

The collaborative projects are purely industry-financed contract research on innovative topics. With practical and high technological know-how for several companies sharing the project expenses. Public funds are not expended and thus the results exclusively benefit the participating companies.

CURRENT PROJECTS:

Werkzeugentlüftung – Rezyklate und nachwachsende Rohstoffe

Herausforderungen und Lösungen in der Werkzeug- und Prozesstechnik

WiUp4U – Wissens-Update for you. Projektteilnehmenden wird aufgezeigt, bestehende Grundlagen und Wissen zur Werkzeugentlüftung mit neuen Ansätzen aus der Werkzeugtechnik zu kombinieren. Dabei wird Know-how aus über 30 Jahren KIMW-Projekten vermittelt, ergänzt durch die neuesten Forschungsergebnisse aus der Werkzeugtechnik.

Warum Sie teilnehmen sollten

Kompakte und praxisrelevante Wissensvermittlung zur direkten Integration in den Arbeitsalltag

Hervorragende Gelegenheit zur Weiterqualifikation der Mitarbeiter

Effizienzsteigerung

Präventive Fehler- und Kostenreduzierung

Austausch mit Projektpartnern und externen Referenten

Projektstart: Juni 2025

Laufzeit: 9 Monate

Technologiescout 6

Always one step ahead

Project content

Project participants receive information about the latest trends, innovations, technologies and products at an early stage. By looking outside the box, impulses are generated for your own development. There is also a constant exchange with project partners and external speakers.

Why you should attend

Technologiescout 6 offers a comprehensive service package at an excellent price-performance ratio:

- project partners do not tie up resources by sending their own staff to trade fairs and conferences

- In addition to the procurement of information, clear documentation in German and English is also provided. Contact Data

- Documents can be quickly and easily forwarded internally to those responsible

- Enabling a mental comparison of the impulses gained with one’s own needs

- Expanding the “field of vision” by looking at other sectors

- Influence on the content and selection of events

Project start: April 2025

Duration: 3 years

The future of plastics in automotive engineering

Trend research and fact check under technical and economic aspects

The automotive industry is changing: e-mobility and sustainability are shaping current developments. What role do plastics play in this? What new requirements do they have to meet? And how can companies in the sector remain competitive?

The project provides answers to these questions.

Why you should attend:

- Trends and facts on the use of plastics in the automotive industry of the future are presented, communicated and documented

- Insights are given into the current trend topics of recyclates/biomaterials, EMC, flame retardancy, decorative surfaces and CO2 footprint

- You receive impulses for the competitive positioning of the industry

- Free participation (funding from the ATLAS transformation network supported by the BMWK)

- Non-discriminatory access

- Three project meetings with presentation of results and specialist presentations to get to know each other and exchange ideas

Project start: April 2024

Duration: approx. 8 months

Initiated and promoted:

Recycling 2

Use of recyclate for technical products

The joint project Recycling 2 focuses on the use of recyclate from various post-consumer sectors for technical applications. In order to better assess the potential uses of these material flows, the project focuses on the following areas

- Characterization of post-consumer recyclates from various sources (e.g. yellow bag, ocean, end-of-life vehicles, e-waste, etc.)

- Examination of batch consistency

- Testing the long-term behavior

- Determination of emissions during processing

- Characterization & improvement of the odor (VOCs ) of recyclates through the use of odor absorbers

Project start: April 2024

Duration: 2 years

Surface Treatment of Plastic Moulded Parts

Carbon Footprint and Saving Potential Analysis | EcoDesign | Trends

Project content

How sustainable are coated surfaces? What product carbon footprint (PCF) do various finishing processes have? What process parameters do have an impact on the PCF and how can this impact be reduced? Research on sustainable plastic materials and coatings is included as well as process combinations and material flows and supply. The basics of EcoDesign will be provided and Life Cycle Analysis will be performed. The basis for the investigations will be components and production processes provided by the project participants.

Why you should attend

- Identification and use of saving potentials

- Knowledge gain and experience in calculation of Carbon Footprint

- Competitive advantage through expertise in use of sustainable materials and processes for your products

- Proof of early activities on sustainability activities and reports for current and future legislation

- Capacity building with minimal personnel and cost effort

- Access to an interactive information and sharing platform exclusively for the project group

- membership in an extensive and strong network – because it is more effective to work on tomorrow’s challenges together

Project start: 1st quarter 2025

Duration: 2 years

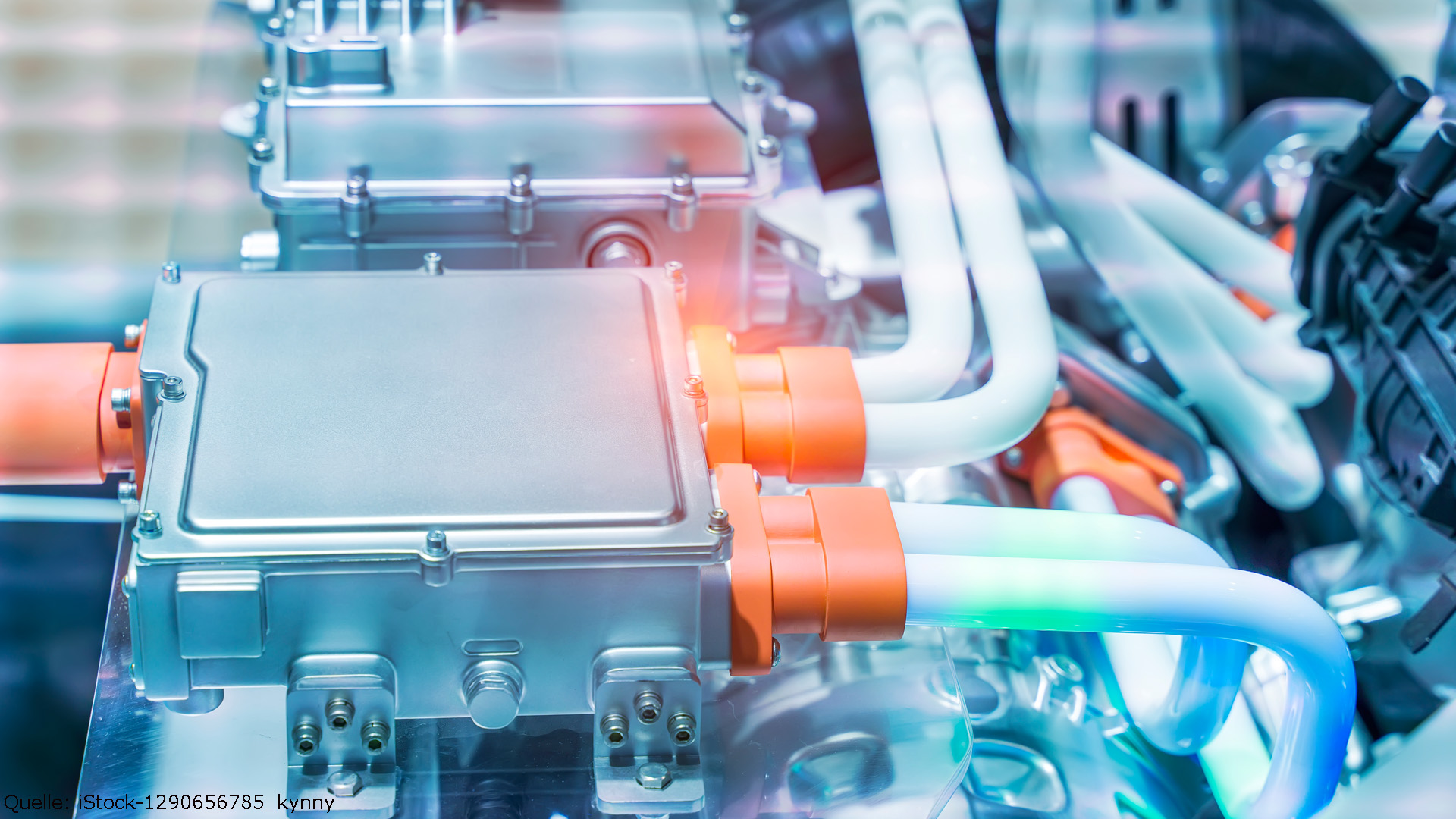

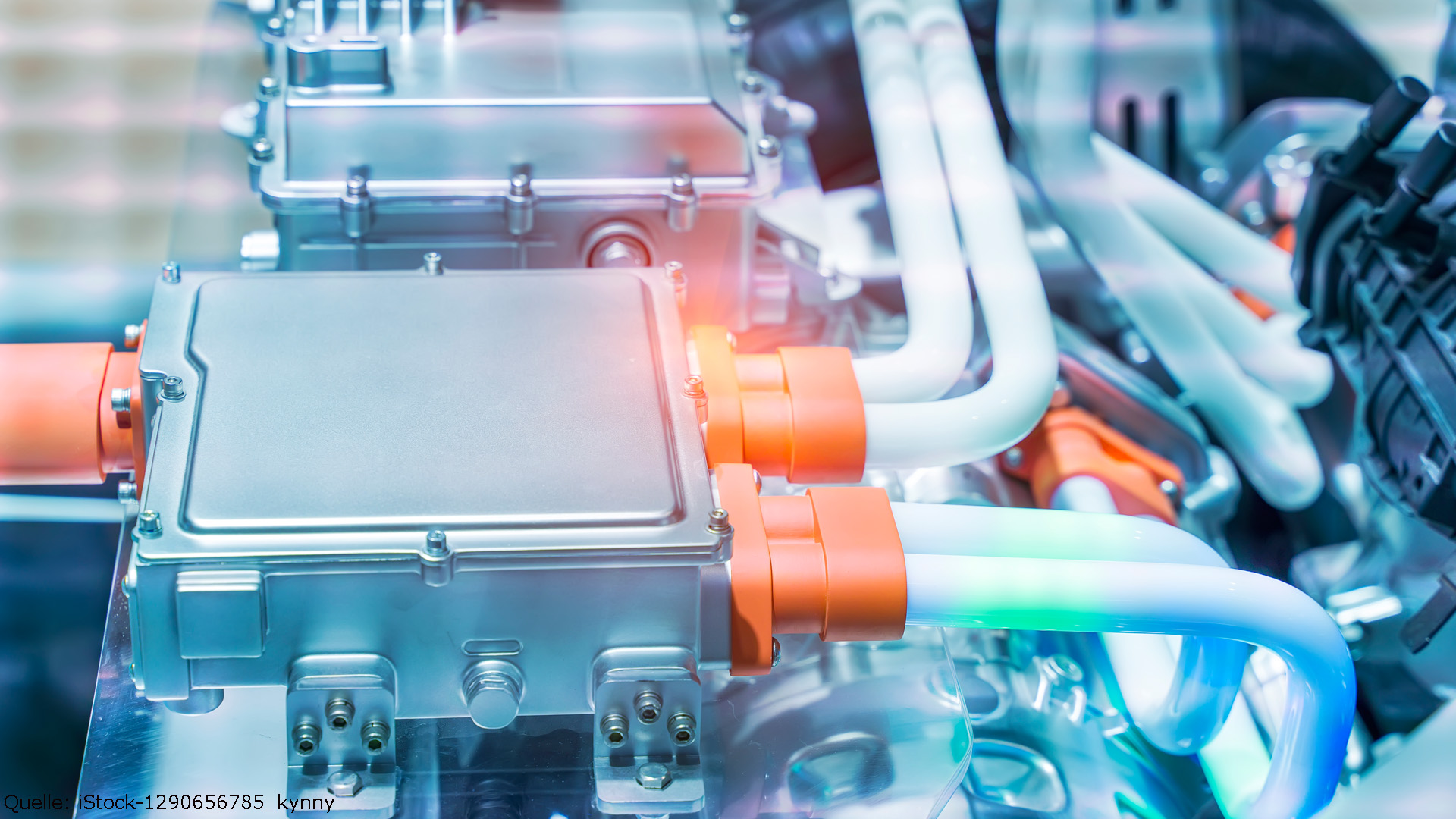

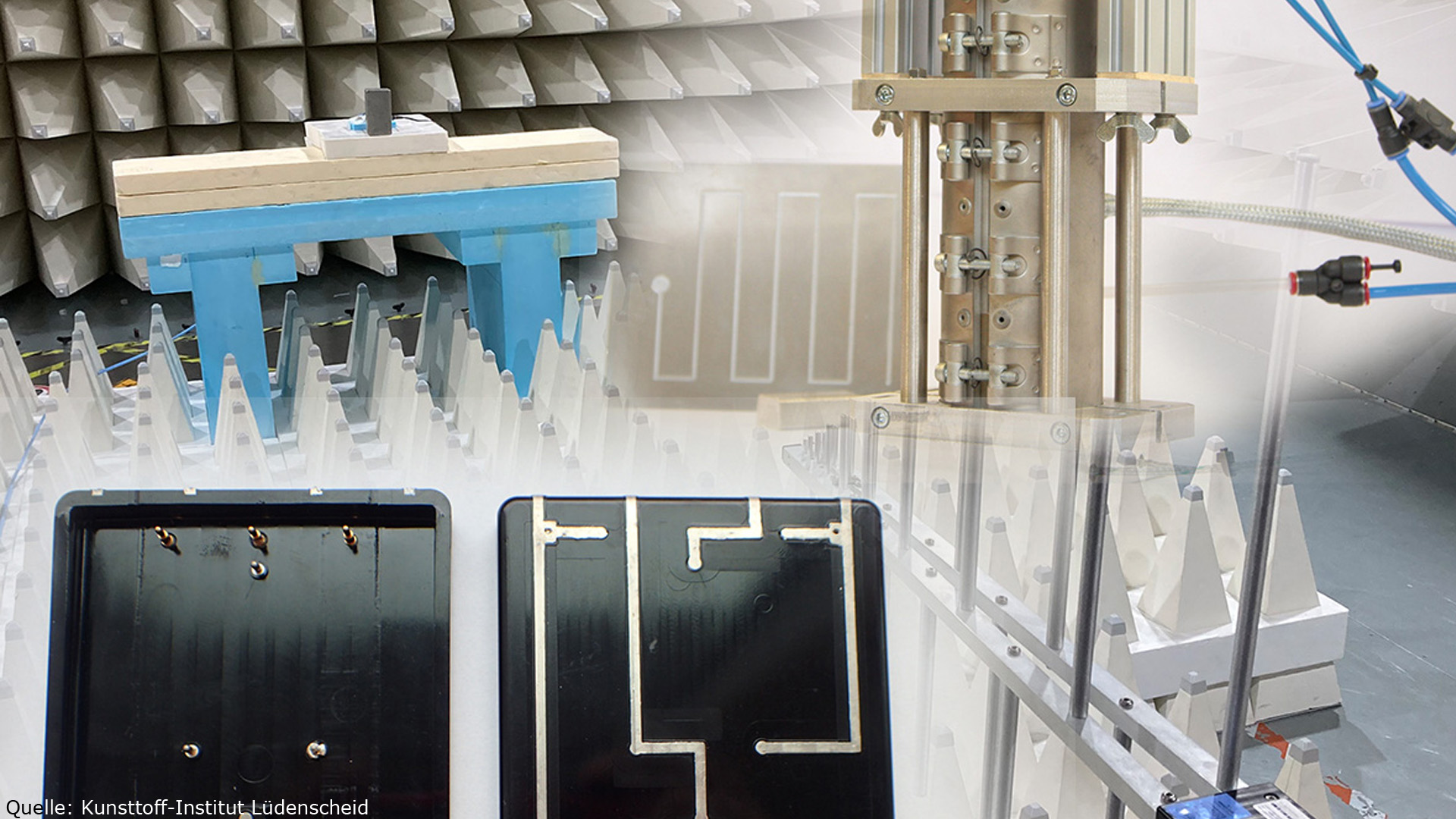

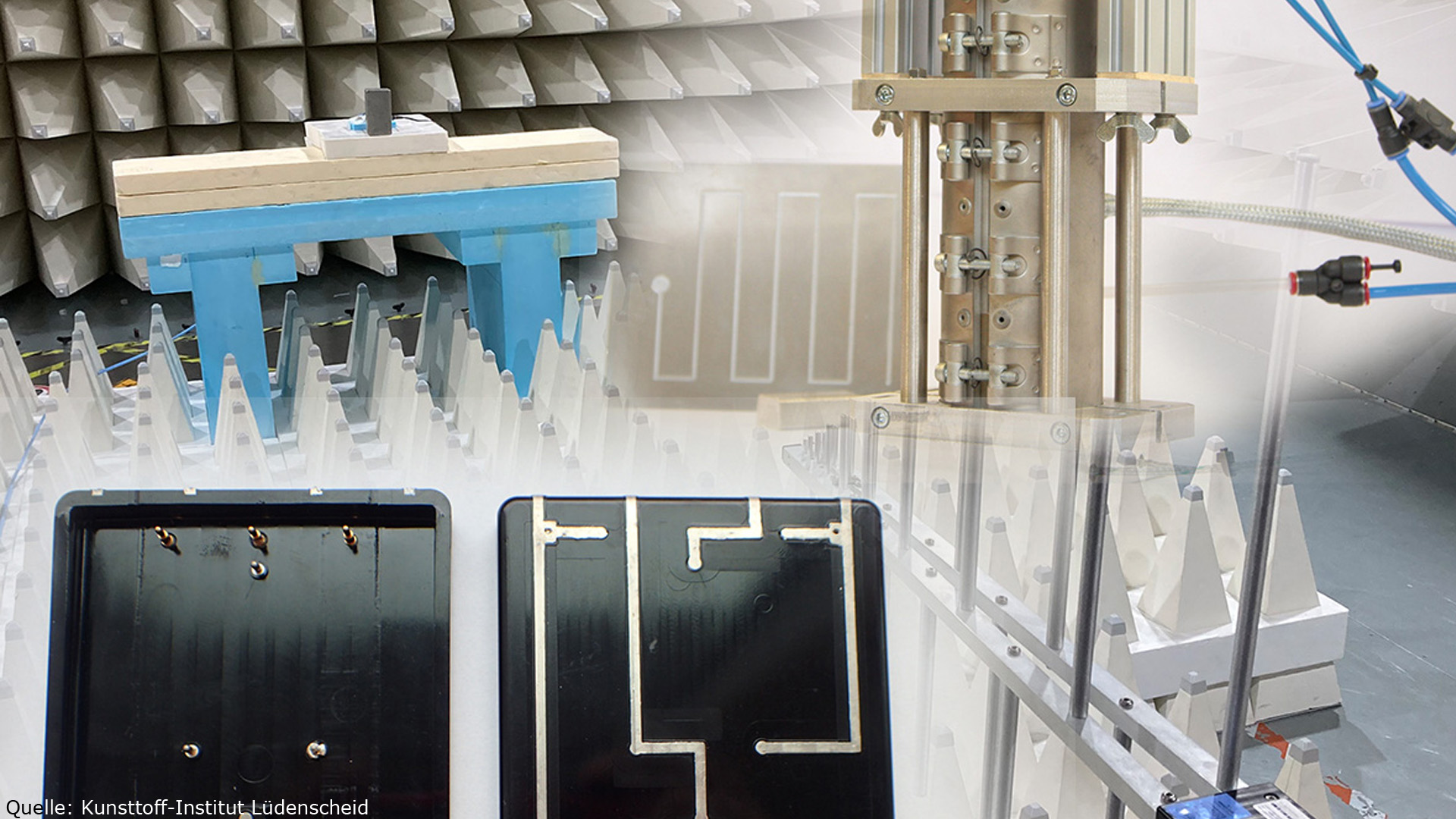

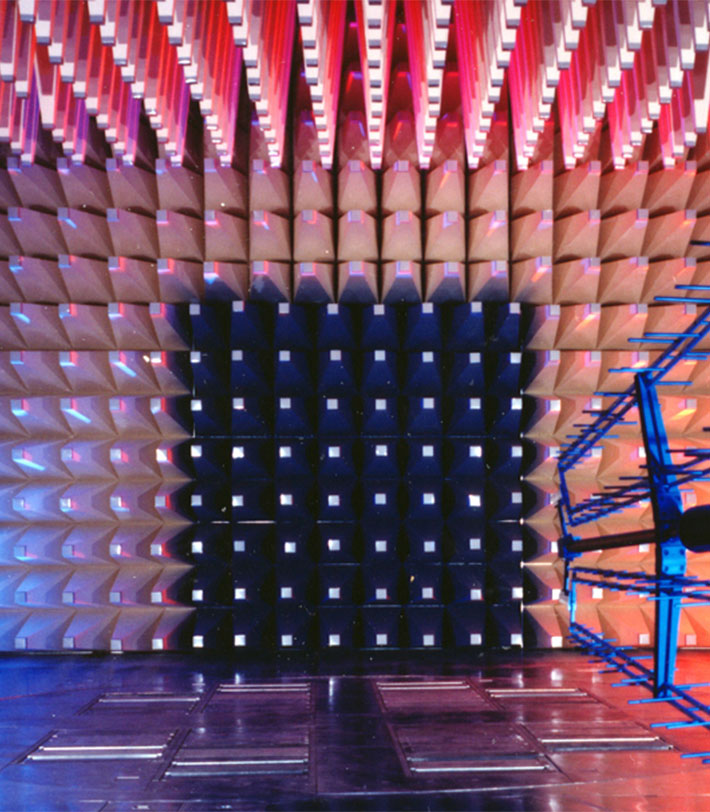

EMV SHIELDING THROUGH PLASTICS 3

MATERIAL SYSTEMS | CONSTRUCTION | METROLOGY

Plastics are often superior to metallic materials, particularly due to lower manufacturing costs, weight savings and sustainability (CO2, recycling, processing temperature). Despite higher compound prices, a plastic solution will become more of a focus in the future in terms of cost-effectiveness and sustainability. E-mobility in particular continues to be a driver for bringing new materials with the function: shielding into use.

Consequently, the Kunststoff-Institut Luedenscheid will offer a 3rd joint project this year with new topics and challenges.

Why you should attend:

- Development of recommendations for the use of plastics for the EMC environment

- Competitive advantage through the use of new material concepts in product development

- Saving of costs and development resources through joint investigations within the project

project start: August 2023

Duration: 2 years

Costs per company: 7.900 Euro annually plus tax

PLANNED PROJECTS:

WiUp4U – Umspritzen von Elektroniken und Leiterbahnen

Herausforderungen und Lösungen in der Material- und Prozesstechnik

WiUp4U – Wissens-Update for you.

Ziel des Projekts ist es, bestehende Grundlagen und Wissen zum Umspritzen von Elektroniken und Leiterbahnen mit neuen Ansätzen aus der Material- und Prozesstechnik für das direkte Umspritzen zu kombinieren. Ein Schwerpunkt dabei ist das Erarbeiten möglicher Potenziale durch geschäumte Thermoplaste.

Warum Sie teilnehmen sollten

kompakte und praxisrelevante Wissensvermittlung zur direkten Integration in den Arbeitsalltag

hervorragende Gelegenheit zur Weiterqualifikation Ihrer Mitarbeiter

Effizienzsteigerung Ihrer Fertigungsprozesse durch das direkte Umspritzen von Elektroniken

- Auf- und Ausbau eines Netzwerks in diesem Technologiebereich

Projektstart: September 2025

Laufzeit: 9 Monate

WiUp4U – Wissens-Update Nachhaltigkeit

Gelebte Nachhaltigkeit in Kennzahlen aufzeigen: Kostenvorteile durch Transparenz identifizieren und anwenden

WiUp4U – Wissens-Update for you. Die Projektteilnehmenden erfahren, wie gelebte Nachhaltigkeit im eigenen Unternehmen in Kennzahlen messbar gestaltet werden kann. Schaffen Sie die notwendige Transparenz, um Kostenvorteile durch nachfolgende Prozessoptimierungen sowie den Einsatz alternativer Materialien für sich anwenden zu können. In nur 6 Monaten erhalten die Teilnehmenden das dafür benötigte Rüstzeug.

Warum Sie teilnehmen sollten

- Praxisnahe Analyse von Nachhaltigkeitsstandards wie die CSRD

- Vorlage zur Erfassung der sozialen Kennzahlen für Ihren Nachhaltigkeitsbericht

- Berechnung des CO2-Fußabdrucks nach ISO 14067 und dem GHG Protocol

- Vorbereitung für eine Registrierung bei Catena-X, SBTi oder ecovadis

- Umsetzungsbeispiele aus unseren Dienstleitungen, Verbund- und Förderprojekten

Projektstart: September 2025

Laufzeit: 6 Monate

EMV Abschirmung durch Kunststoffe 4

Materialsysteme | Konstruktion | Messtechnik

Das Projekt fokussiert sich auf den gezielten Einsatz von niedrig schmelzenden Metallen in leitfähigen Kunststoffanwendungen zur Verbesserung der EMV Eigenschaften. Innerhalb des Projekts sollen sowohl neue Materialansätze sowie Konstruktionsprinzipien und Verarbeitungstechnologie praxis-/anwendungsnah verfolgt werden.

Warum Sie teilnehmen sollten

- Erarbeitung von Handlungsempfehlungen für den

Einsatz von Kunststoffen für das EMV-Umfeld - Wettbewerbsvorteil durch Einsatz neuer Materialkonzepte in der Produktentwicklung

- Einsparung von Kosten und Entwicklungsressourcen durch Gemeinschaftsuntersuchungen innerhalb des Projektes

- Wissenstransfer und Technologievorteile neuer Material und Fertigungskonzepte

- Geringer Personal- und Kostenaufwand zur Realisierung von neuen Lösungen in Bezug auf die Produktentwicklung

- Netzwerkzugehörigkeit im Themengebiet

Projektstart: September 2025

Laufzeit: 1,5 Jahre

Smart ProDat

Use process data sensibly with manageable effort

Project content

Get to know the possibilities of AI together with the experts from Kistler Instrumente GmbH and KIMW.

Determination and discussion of relevant machine and process data. Use of AI-supported software to identify disturbance variables and potential for improvement.

Why you should attend

- Recognize requirements for the successful use of data-based quality assurance

- Identify relevant data records and create process transparency

- Targeted detection of reasons for rejects and optimization potential

- Derive well-founded decisions for the introduction of the right technologies

- Improve process stability (e.g. in the event of material fluctuations due to the use of recyclate) using data-based methods

- Building skills for the successful implementation of AI projects in production

- Providing employees with the best possible support

- Expand network in the subject area

Project start: November 2024

Duration: 1 year

COMPLETED PROJECTS:

BIOPOLYMERE

WERKSTOFFE, EIGENSCHAFTEN, NACHHALTIGKEIT

Der Faktor Material stellt innerhalb der Bauteilproduktion nicht nur kostentechnisch, sondern auch energetisch den Hauptaspekt dar. Daher muss die Steigerung der Nachhaltigkeit zwangsweise auch über den Materialeinsatz führen. Die Etablierung einer Kreislaufwirtschaft ist hier natürlich eine Option, aber nicht für jedes Unternehmen oder Produkt die Lösung.

Der Einsatz von biobasierten und/oder biologisch abbaubaren Polymeren, ggf. in Kombination mit der Kreislaufwirtschaft, kann insbesondere eine Lösung darstellen.

Aber welche Materialien und Rohstoffhersteller gibt es? Welche Eigenschaften besitzen diese Werkstoffe und inwieweit lassen sich Eigenschaften anpassen und wo sind die Grenzen?

Die Projektteilnehmer in die Lage versetzt, selbst beurteilen zu können, welche Materialien für die eigenen Produkte eingesetzt werden können, und, ob diese die Nachhaltigkeit des Produktes erhöhen.

Weitere Einzelheiten entnehmen Sie bitte dem Projektflyer.

Projektstart: November 2022

Projektlaufzeit: 1 Jahr

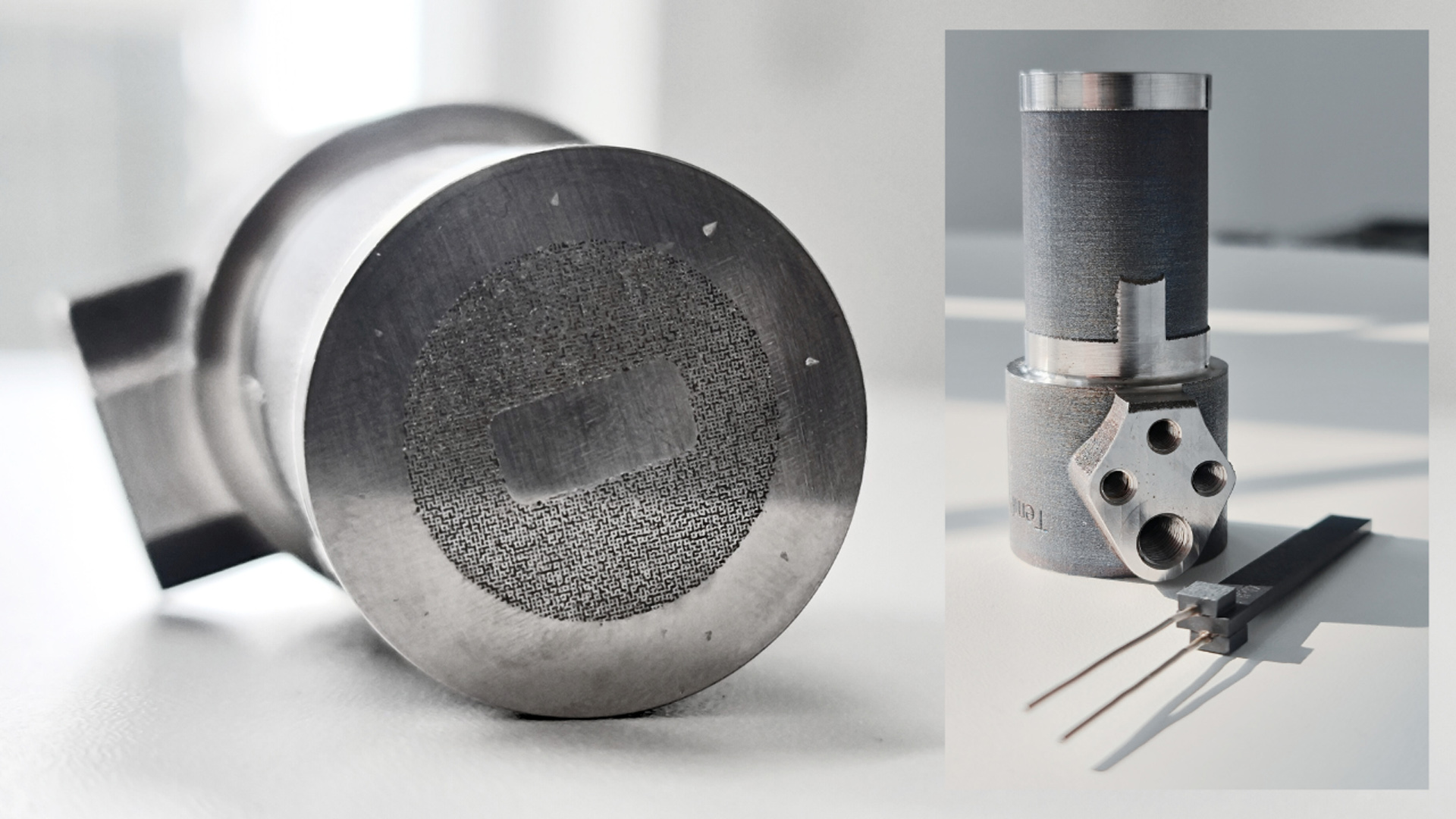

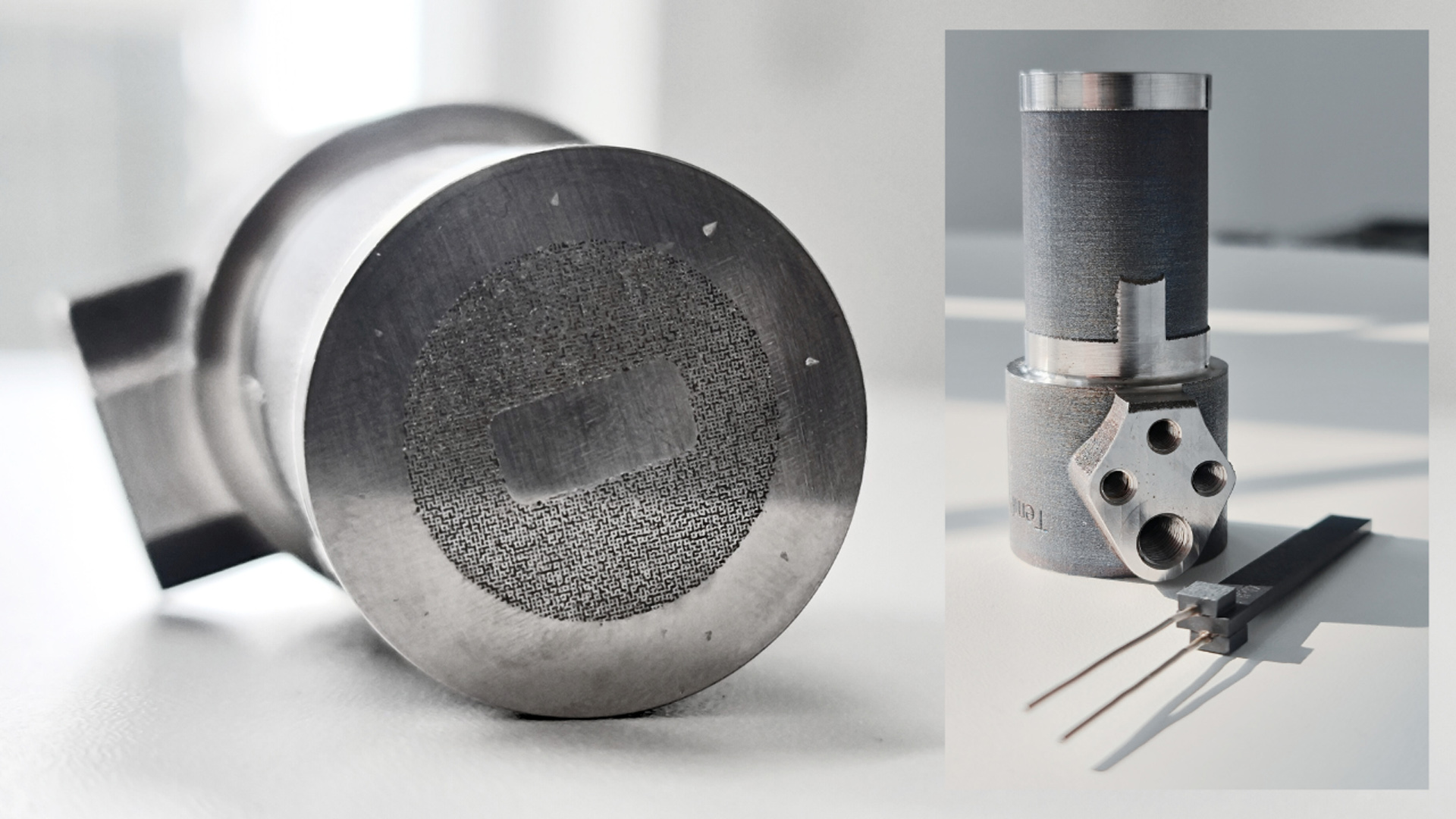

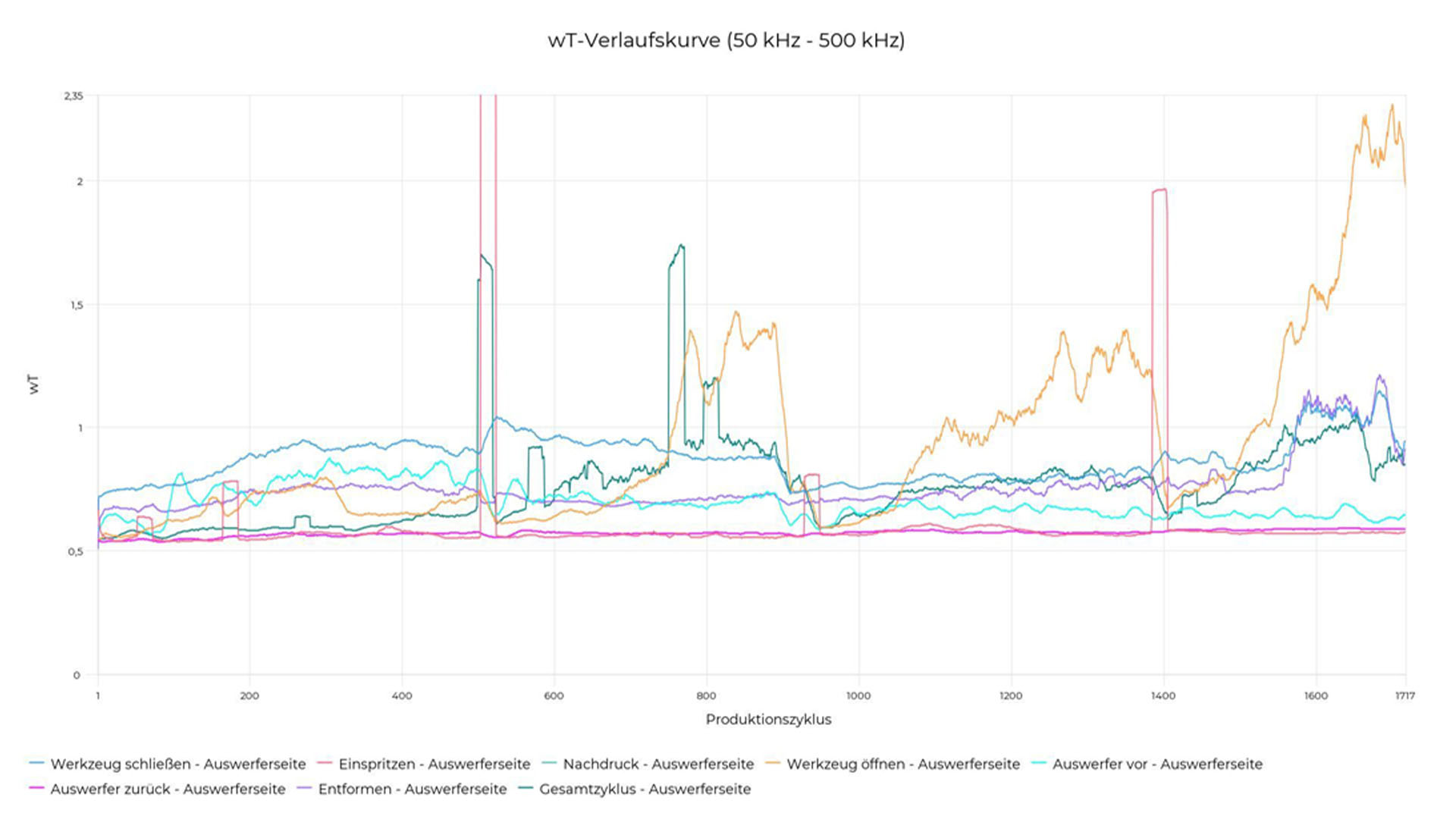

SMART-MONITORING 2

EINSATZ VON KÖRPERSCHALL IN SPRITZGIEßWERKZEUGEN

In Zusammenarbeit mit der Fa. wearTELL Deutschland GmbH planen wir das Anschlussprojekt „Smart Monitoring 2“ zum Einsatz von Körperschall in Spritzgießprozessen.

Zu den Projektleistungen gehören:

- Schulungen zu den bisherigen Themen

- Verschleißerkennung im Werkzeug

- Produktionsfehler und Einstellung von Grenzwerten

- Einsatz und die Auswertung von multiplen Sensoren

- Vermessen von multiplen Fließfronten oder unterschiedlich großen Kavitäten

- Verschleiß Spritzgießmaschine messbar machen, z. B. Rückstromsperre, Schmierzustände an Holmen etc.

Ausührliche Projektinformationen finden Sie hier.

Projektstart: November 2022

Laufzeit: 10 Monate

ZUKUNFTSFELD PAPIERSPRITZGUSS 3

KOMPOSTIERBARE MATERIALIEN

In der Projektfortführung werden die Optimierungsmöglichkeiten der bisher untersuchten kompostierbaren Materialien aber auch Potentiale zusätzlicher Materialien mit vergleichbarem Abbauverhalten untersucht.

Warum Sie teilnehmen sollten:

- Wettbewerbsvorteil durch zukunftsfähige Materialalternativen

- Einsparung an Kosten und Entwicklungsressourcen durch Gemeinschaftsuntersuchungen innerhalb des Projektes

- Geringer Personal- und Kostenaufwand durch Unterstützung von KIMW – Mitarbeitern

- Kein Invest durch Bereitstellung von erforderlicher Abmusterungs- und Laborkapazitäten

- Wissenstransfer und/oder Know-how Aufbau für Ihre Mitarbeiter

- Netzwerkzugehörigkeit im Themengebiet

- Verbesserung der Umweltbilanz

- Signalwirkung für Kunden

Projektstart: Oktober 2022

Projektlaufzeit: 1 Jahr

RECYCLING

USE OF RECYCLATE FOR TECHNICAL PRODUCTS

The project aims to answer the most critical questions concerning the topic of recyclate. In addition, a systematic approach for the use of technical recycling materials in existing processes and products will be developed using exemplary examples.

Why you should attend:

- Early entry into the topic of recyclate use

- Ensuring competitiveness in the event of future legislative changes

- Evidence of early activities for existing and upcoming OEM requirements.

- Reduction of the carbon footprint of our own plastic products

- Spotlighting new business models in the context of take-back systems

- Proof of sustainability for your marketing and public relations activities

Project start: Oktober 2022

Duration: 1,5 years

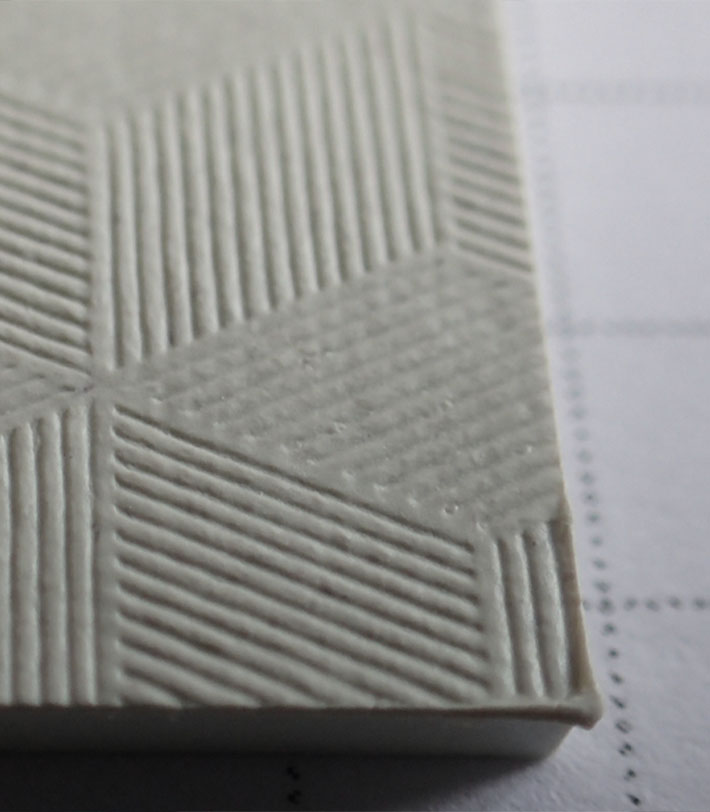

PVD COATING OF PLASTIC PARTS 3

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

The desire in the decorative field to apply a robust PVD coating directly to the plastic substrate or a PVD layer to a primer coating without a protective coating in order to save process costs, minimize scrap, obtain a better gloss image, be able to perfectly reproduce textured plastic surfaces or realize a precoating for electroplating is often clouded by low adhesion or the mechano-chemical fragile properties of the overall system. This project demonstrated the potential of HiPIMS technology for these aspects.

INDIVIDUAL CO2 BALANCE

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

The central purpose of the project was to develop a common understanding and a uniform approach for determining the product environmental footprint. In addition, a CO2 balance sheet was drawn up in practice using the example of the technical center at the Kunststoff-Institut, and recommendations for action were developed.

The project has shown that there are many individual ways to balance processes, which makes comparability difficult. In addition, benefits can be achieved through technical measures.

EMV SHIELDING THROUGH PLASTICS 2

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

Due to new design concepts and simultaneous technical function integration, cases of electronic components require innovative solutions with regard to the material. Electrically conductive plastics can contribute to the trouble-free operation of electronic systems, particularly with regard to shielding against electromagnetic radiation. Technology drivers are advancing digitalization, electrification and the increase in radio applications in the automotive, electronics, household or medical sectors. Devices must function or interact side by side without unintentionally influencing each other.

On the one hand, the project dealt with material technology issues. Conductive plastics for EMC applications, based on fillers such as carbon, steel or conductive carbon black, are nowadays well established. The use of the fillers increases the stiffness of the material, but at the same time reduces important housing properties such as impact strength and elongation at break. The toughness and elongation of conductive plastics can be optimized by using modifiers. Currently unresolved is the effect on conductivity and shielding effectiveness, which are being investigated in this project.

On the other hand, the connections of case components (e.g. by screws) require special consideration with regard to the joining situation. In contrast to metallic materials, plastics exhibit increased contact resistance in the joining area, which has a detrimental effect on the shielding behavior. By choosing more suitable geometry modifications, the penetration and leakage of electromagnetic waves can be prevented. The study of the influence of geometry variation was initially performed using 3D printing. This was followed by the injection molding of cases to evaluate the influence of different materials.

ANTIMICROBIAL SURFACES 2

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

The term “biocide” describes the property of a substance to prevent or reduce the emergence of bacteria, viruses or fungi. In the context of the collaborative study, the focus was on antibacterial efficacy. The growth of microbes and germs on surfaces is an undesirable effect in many respects, as it poses a hygiene risk, impairs the utility value of surfaces or leads to food spoilage.

The demand for biocide-treated surfaces has increased enormously in recent times, leading to a useful functional improvement in many products. Within the study, basic principles of antimicrobial action are shown and the possibilities of surface modification for plastics are presented. Different antimicrobial systems were researched, system suppliers were listed, the development status was scrutinizes and the application possibilities were differentiated.

FOAMING IN INJECTION MOLDING PROCESS

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

As part of the joint project “Foaming in injection molding”, the properties of components produced by thermoplastic foam molding (TSG) were scrutinized as a function of material, process and process parameters.

For example, the question of the achievable degrees of foaming and how these influence the mechanical properties was answered. There were also insights into which tests and measured values correlate best with the requirements of real components and how component stresses and environmental influences affect the properties.

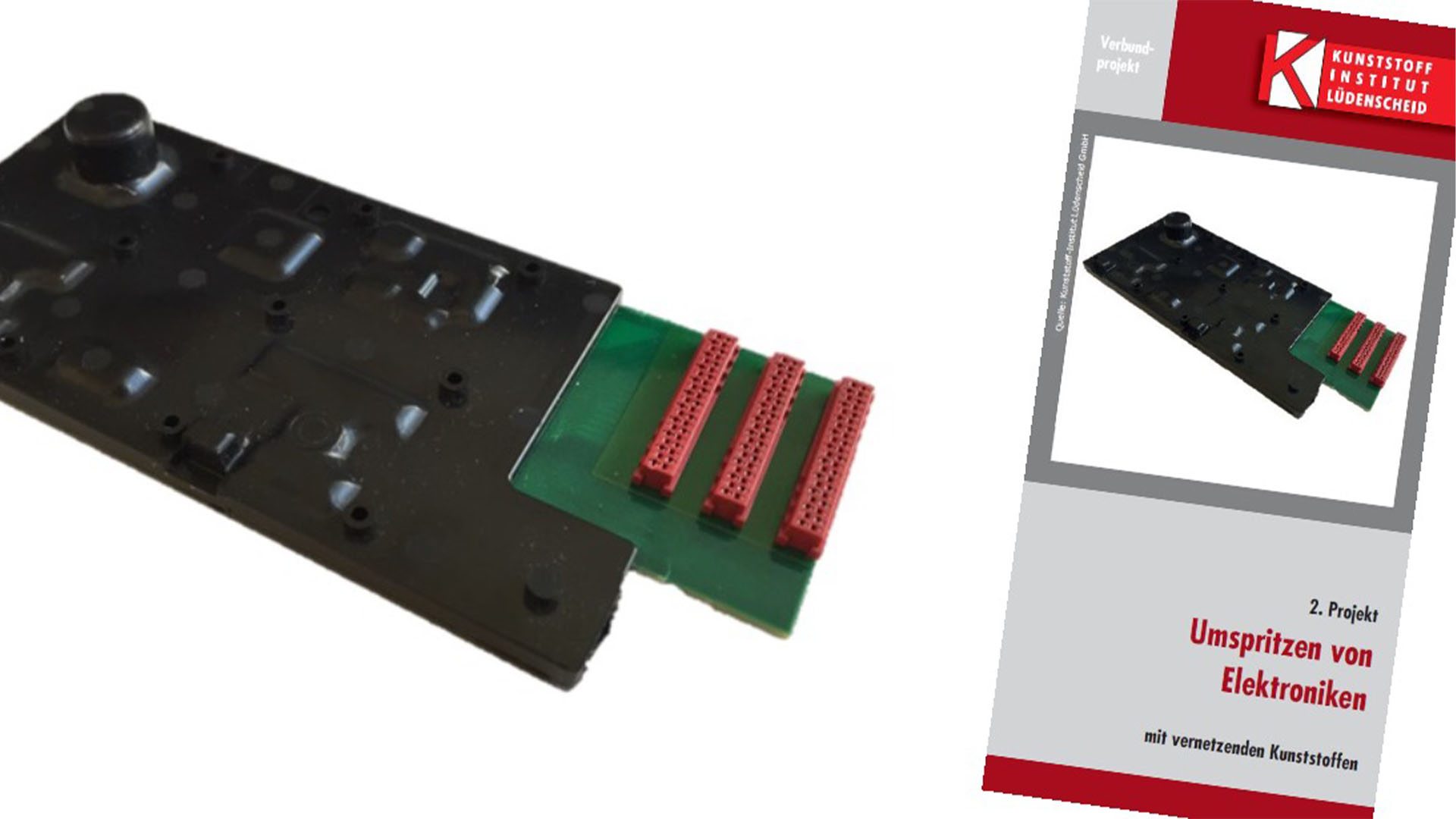

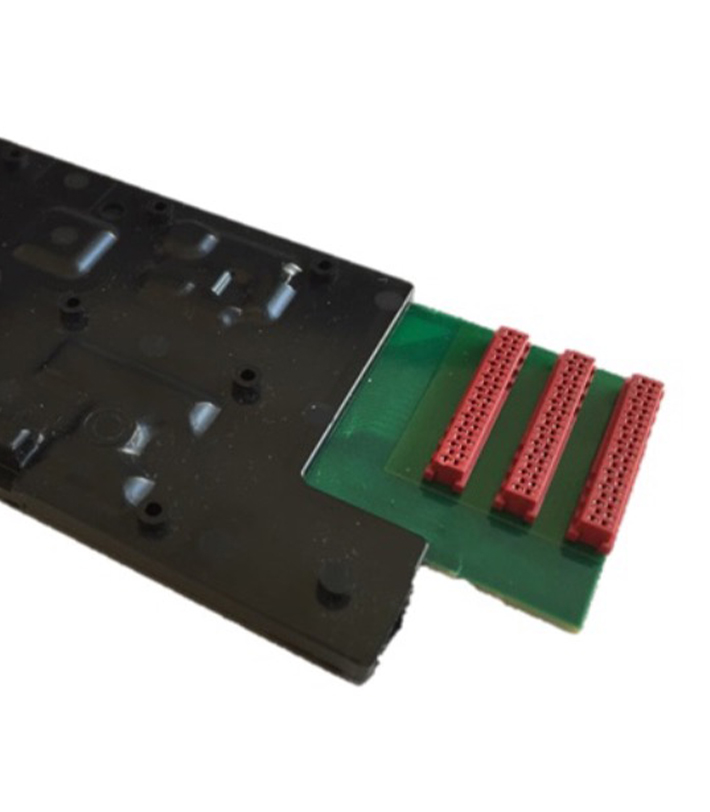

OVERMOLDING ELECTRONICS 2

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

In the project “Overmolding of electronics”, the possibilities of encapsulating electronic components were to be further developed. Two focal points were set for this purpose. On the one hand, the aim was to validate the influence of the molding compounds and process parameters on the function of electrical components; on the other hand, the media tightness of different cable, molding compound combinations was investigated.

In the first project focus, a printed circuit board was designed which was equipped with different electronic components (electrolytic capacitors, ICs, Hall sensors, etc.). For this purpose, a measuring stand was developed with which it was possible to test the function of all components at component level. The printed circuit boards were encased in various thermoset molding compounds and molding parameters and subjected to a selection of component stresses. The function of the components was checked “fresh from the spray”, in the cooled state and after the component stresses. With many parameter settings, almost no influence on the function of the components could be determined.

For the second project focus, different cable materials were coated with the same molding compounds and process parameters. These test specimens also underwent component stressing. To determine the media tightness of the molded compound – cable combinations, the leakage rates were determined by means of pressure drop testing. Here, depending on the cable type, very high sealing densities could be determined.

CONTACT

LOREM IPSUM DOLOR SIT AMET

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur.

MAX MUSTERMANN

DIPL. WIRT.- ING.

MANAGEMENT AREA XXX

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

MAX MUSTERMANN

DIPL. WIRT.- ING.

MANAGEMENT AREA XXX

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

MAX MUSTERMANN

DIPL. WIRT.- ING.

MANAGEMENT AREA XXX

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

MAX MUSTERMANN

DIPL. WIRT.- ING.

MANAGEMENT AREA XXX

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

MAX MUSTERMANN

DIPL. WIRT.- ING.

MANAGEMENT AREA XXX

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

KONTAKT

KONTAKT

Wir sind für Sie da!

HOTLINE

HOTLINE

Wir freuen uns auf Ihren Anruf

+49 (0) 2351 1064 -191

Für Sie erreichbar

Mo bis Do: 8:00 – 17:00 Uhr

Fr: 8:00 – 15:00 Uhr

Möchten Sie weitere Informationen zu unseren Produkten? Wir helfen Ihnen gerne weiter.