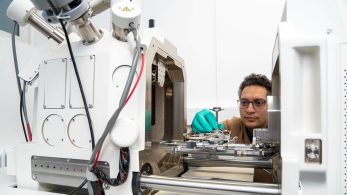

APPLICATION CENTER FOR SURFACE TECHNOLOGY (AOT)

Heat-conductive plastics are increasingly coming into focus within innovative development processes. There are many reasons for using thermally conductive plastics: economical production, lightweight construction, new assembly concepts, high design freedom, functional integration and the possibility of targeted plastic additives. However, a 1:1 substitution of existing materials within an assembly is not always effective. As a result of the high filler content and the associated loss of mechanical properties (elongation and toughness), the realization of e.g. snap-on hooks, fasteners, etc. on housings or other components is hardly feasible. The 2-component technology will be used to investigate the use of multi-materials with regard to the adhesion of the material systems, with the aim of being able to use thermally conductive plastics only in partial areas where heat dissipation is necessary.

In the course of increasing demands on materials, the topic of flame retardancy came to the fore in areas of E&E as well as in electromobility. Often, based on the requirements, a material classification UL94 V-0 is required by halogen-free flame retardants. Within the project, flame retardant systems available on the market were to be specifically investigated in the context of thermally conductive plastics based on material compounding with regard to thermal conductivity, mechanics, processability and flame retardancy.

Finally, the market for heat-conductive plastics is growing steadily, so a broader portfolio of materials is needed to give users more room for maneuver in the concept phase. In the previous projects, investigations were carried out exclusively with polyamide and polycarbonate materials. These results were then applied to other matrix systems.