DURATION: 07/21 - 04/22

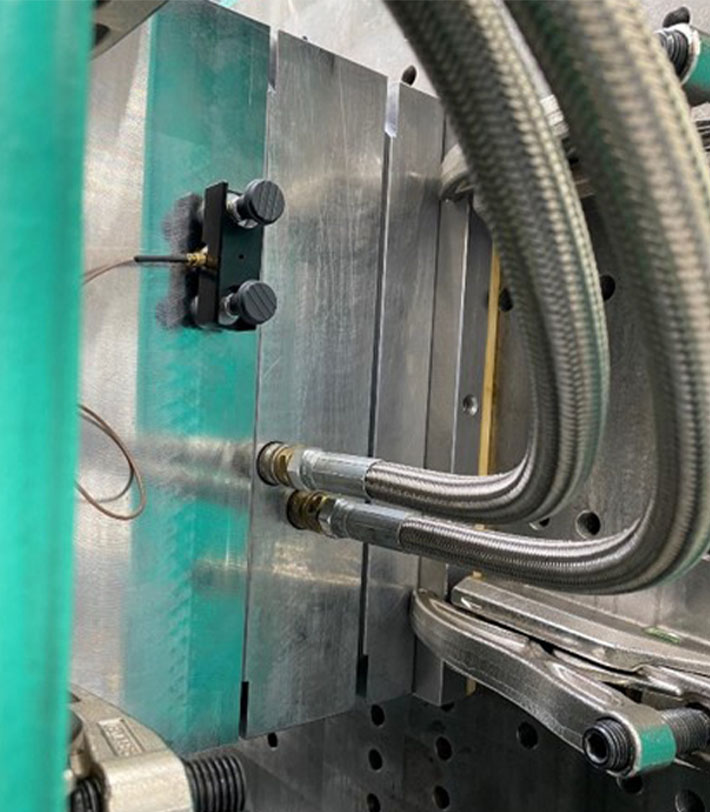

In the processing of plastics in injection molds, questions repeatedly arise regarding maintenance and servicing intervals, which should be answered by recording structure-borne sound waves.

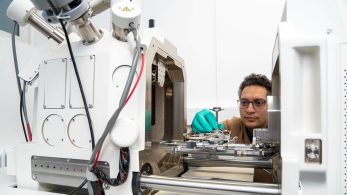

Concept: Detection of structure-borne sound waves propagated by transient waves – resulting from friction or fracture – in solids.

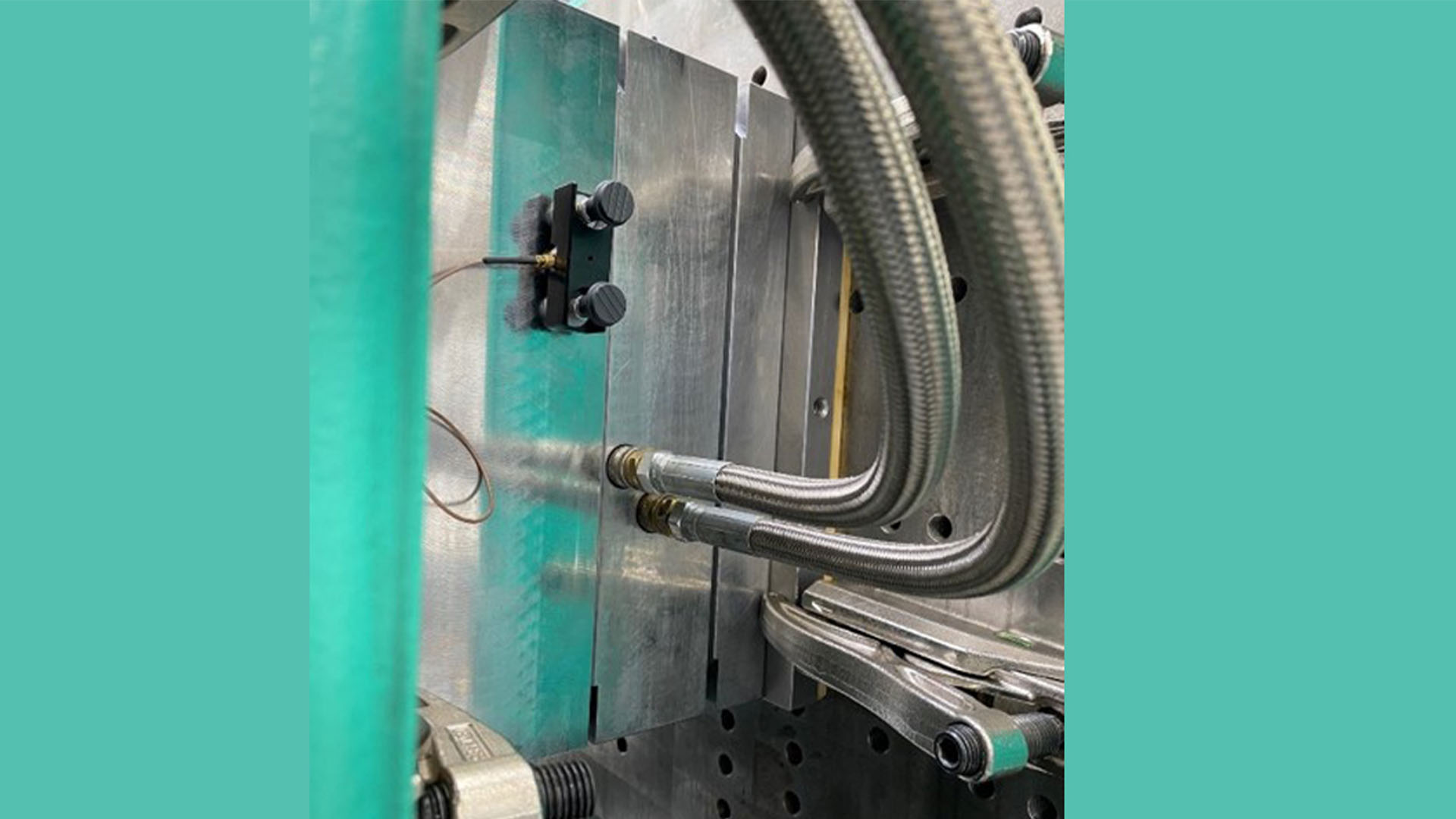

Purpose: To apply the measuring procedure to injection molds by means of a contacting structure-borne sound sensor (piezoelectric effect), which can be relatively easily attached to the outside of a mold by means of magnets.

Each mold element and each phase of the injection molding process generates an individual, acoustic “fingerprint”. This “fingerprint” is intended to record and evaluate changes in running processes, which should provide information about changes in the mold:

- Structure of coverings

- Clogging of vents

- Change of demolding forces

- “Stick-slip” effects in lubricated systems

- Cracking / breakage (e.g. gate valve, ejector)

The project is being carried out in close cooperation with wearTell Vertriebsgesellschaft mbH & Co. KG from Bochum, which is also providing the necessary technical equipment and accompanying the company-specific investigations in the project. The project is limited to a number of participants of 10 project companies and was already successfully launched in July 2021.