Know-how for your success.

Our research activities are focused exclusively on practical issues and their solutions. Interdisciplinary cooperation, excellent networking in the industry and research landscape flank our activities.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

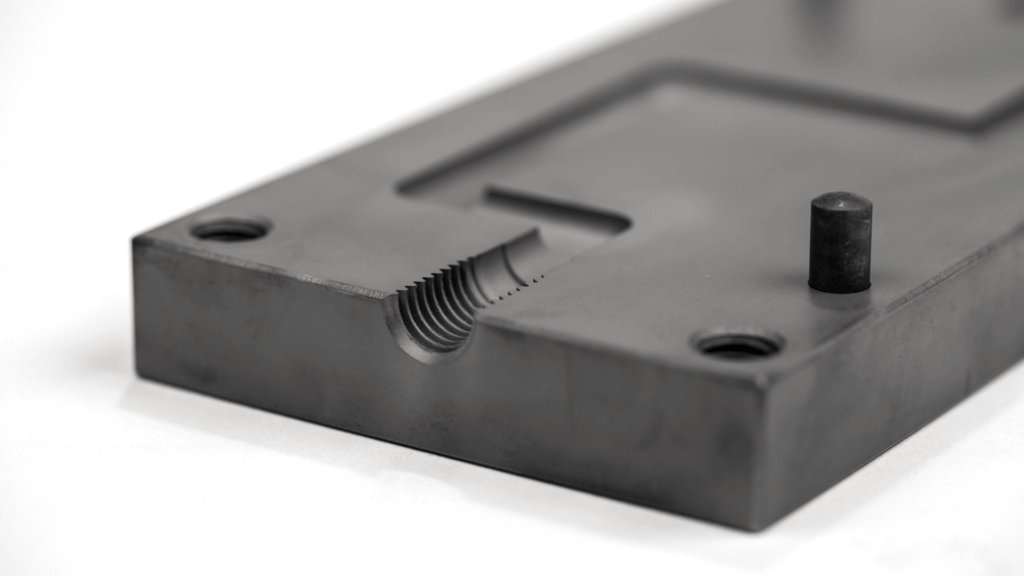

A wide range of layering properties often exceed the performance of solid materials. Thus, in the form of thin layers, extreme wear resistance up to diamond hardness, favorable friction properties of graphite, chemical resistance such as Teflon or temperature resistance of ceramics can be achieved. In combination with selected base materials, innovative materials can be designed that are indispensable in modern manufacturing processes.

Machining and stamping tools receive extreme wear protection, and injection molding and die casting tools are protected from buildup and cold welding by coatings. Turbine blades or components for the chemical industry are given high-temperature-resistant or corrosion-resistant surfaces.

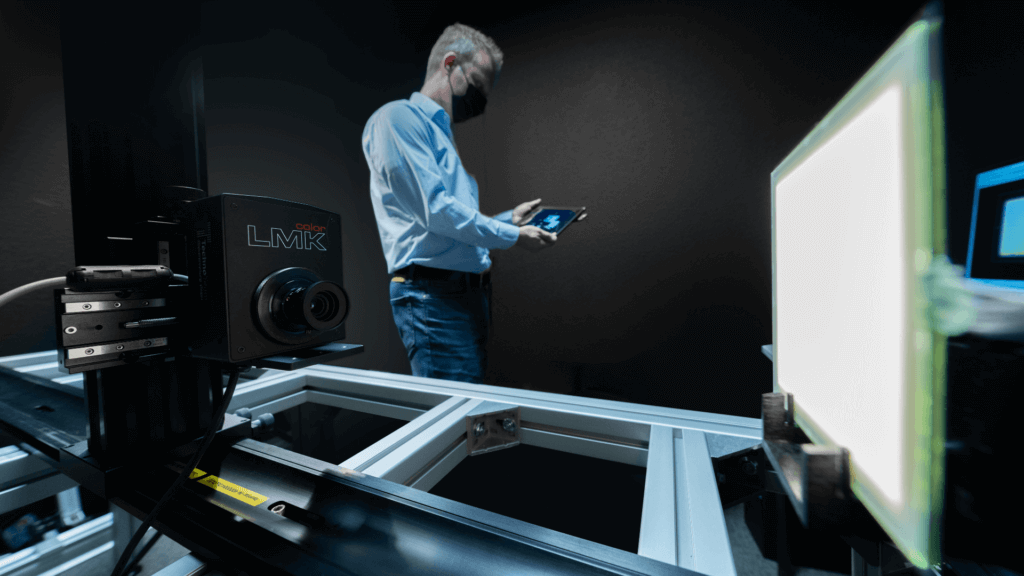

Lighting technology has undergone rapid development

in recent years. In addition to a variety of technological developments in the field of light source, such as those of LED and OLED technology, the requirements for the functionality of components and assemblies made of plastic for lighting applications have also been constantly increasing. The assemblies are responsible in particular for the targeted light guidance, light control and light output and have a significant influence on the quality.

A diverse range of research and services is available for developers and users from a wide variety of industrial sectors

Tools are at the heart of many manufacturing processes. They are subject to constant change with regard to increasing quality and efficiency requirements. A major focus of work is the new and further development of tools for plastics processing to increase productivity and component quality and to reduce necessary process energies.

Focuses

Process technologies have a significant influence on the economic efficiency, quality and CO2 footprint of products. In response to changing requirements, such as in the areas of lightweight construction or integrative production processes, we research and develop manufacturing processes for plastics processing.

Focuses

In all areas where safety aspects such as fire protection or hygiene play a role, the highest demands are placed on the plastic components used there.

This is particularly the case for electronic devices, in the textile industry, in the construction industry, the automotive industry, for housings and devices as well as surfaces in the medical sector.

In order to equip plastic components and surfaces with appropriate functionalities, we deal with

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

I appreciate the KIMW because of the high practical relevance of the content. As a manufacturing, medium-sized company, we need concretely effective information and training to increase our productivity, not outlooks on theoretically possible technologies from Silicon Valley.

With more than 30 years of practical experience and know-how in the plastics industry, we see ourselves as an ideal partner in the field of contract research. The goal-oriented and above all practice-oriented execution of R&D projects for profitable solutions and implementations. From the idea to practical implementation is our claim.

Short, promotional text about the flyer, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

We use our equipment for the determination of material and component specific properties and are not only able to serve your standard tasks, but also to support you professionally for the improvement of your results and less conventional questions. The close interlocking with the other specialist departments of the KIMW guarantees you the highest level of know-how, practical complete solutions and thus the best possible service for your concern.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus.

You want more information? Then follow the cross references, call us or visit us for a personal institute presentation in Luedenscheid.

You are not only looking for a laboratory that determines pure data for you, but a partner who supports you in all questions and at any time?

Contact us and test us – we are here for you.

INQUIRIES BY E-MAIL TO TESTING@KIMW.DE OR USE OUR OFFER CONFIGURATOR

You want more information? Then follow the cross references, call us or visit us for a personal institute presentation in Luedenscheid.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

– More than 100 specialists in materials, process, tool, surface, process and test engineering work for you at the Kunststoff-Institut

– 12 injection molding machines (8 of them with insertion and removal automation)

– Competence Center for Thermoset Processing

– Unique application center for surface technology

– Comprehensive measurement technology for injection molding process optimization

– Over 100 systems for material, component and surface testing

– Annual turnover: around 10 million euros

– Alone settings in Europe:

– Largest provider of round robin tests in plastics technology

– Application center for surface and decorating processes

– The only “gold-labeled” plastics institute within the scope of Cluster Excellence

– In our business units, we work extensively on the innovation fields listed below in service, research and development.

– We provide training and internships for students.

– More than 100 specialists in materials, process, tool, surface, process and test engineering work for you at the Kunststoff-Institut

– 12 injection molding machines (8 of them with insertion and removal automation)

– Competence Center for Thermoset Processing

– Unique application center for surface technology

– Comprehensive measurement technology for injection molding process optimization

– Over 100 systems for material, component and surface testing

– Annual turnover: around 10 million euros

– Alone settings in Europe:

– Largest provider of round robin tests in plastics technology

– Application center for surface and decorating processes

– The only “gold-labeled” plastics institute within the scope of Cluster Excellence

– In our business units, we work extensively on the innovation fields listed below in service, research and development.

– We provide training and internships for students.

Tel: +49 2351 1064-198

E-mail: hinzpeter@kimw.de

Tel: +49 2351 6799-911

E-mail: frettloeh@kimw.de

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

Tel: +49 2351 1064-134

E-mail: librizzi@kimw.de

Tel: +49 2351 6799-911

E-mail: frettloeh@kimw.de

Tel: +49 2351 1064-xxx

E-mail: mustermann@dir-kimw.de

Wir sind für Sie da!

Wir freuen uns auf Ihren Anruf

+49 (0) 2351 1064 -191

Für Sie erreichbar

Mo bis Do: 8:00 – 17:00 Uhr

Fr: 8:00 – 15:00 Uhr

Möchten Sie weitere Informationen zu unseren Produkten? Wir helfen Ihnen gerne weiter.

Bitte füllen Sie das folgende Formular aus, um das Whitepaper herunterzuladen.