Technology that not only fits -

but also thinks ahead

Technical developments Developed with practical relevance. Precisely implemented.

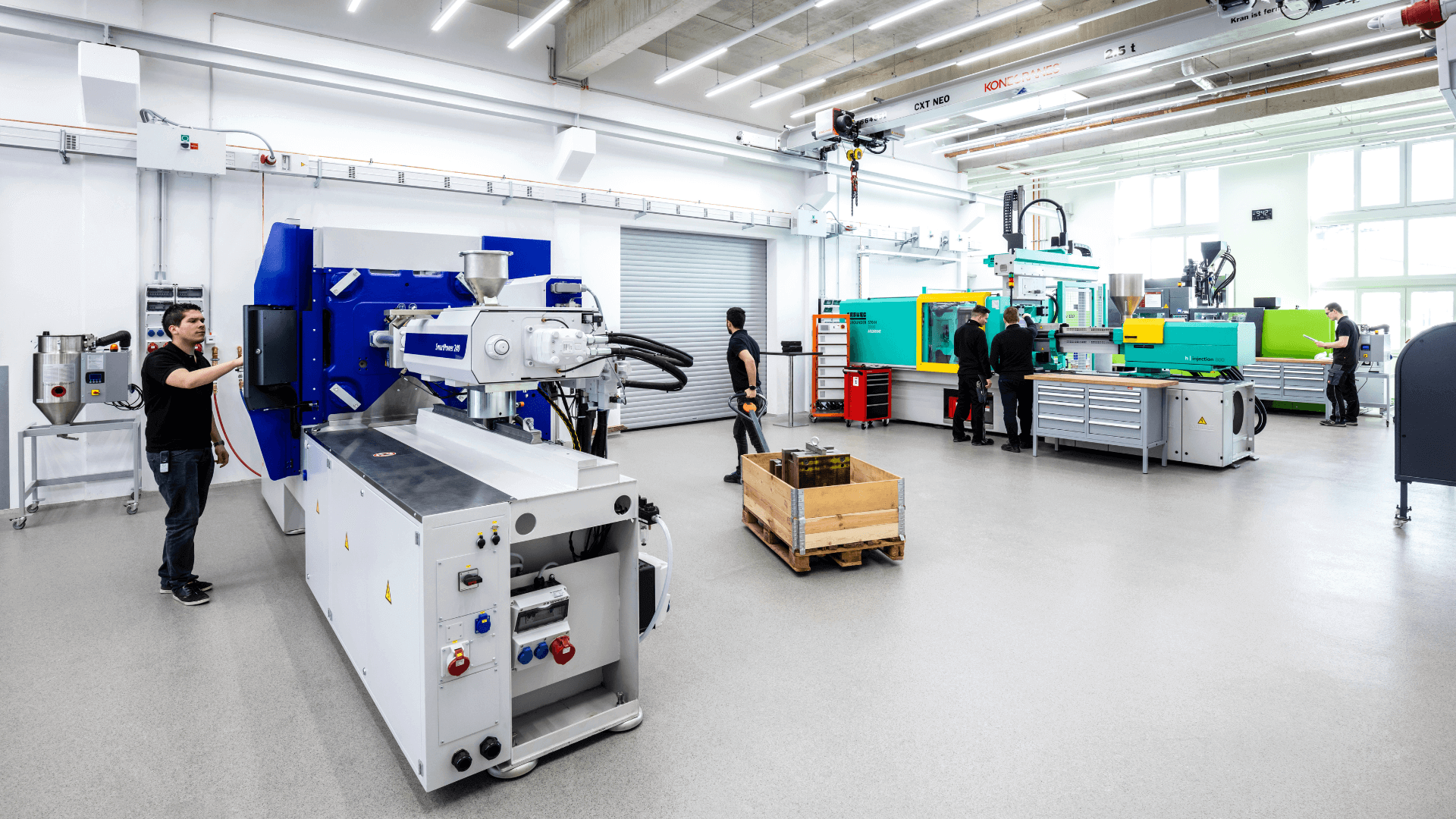

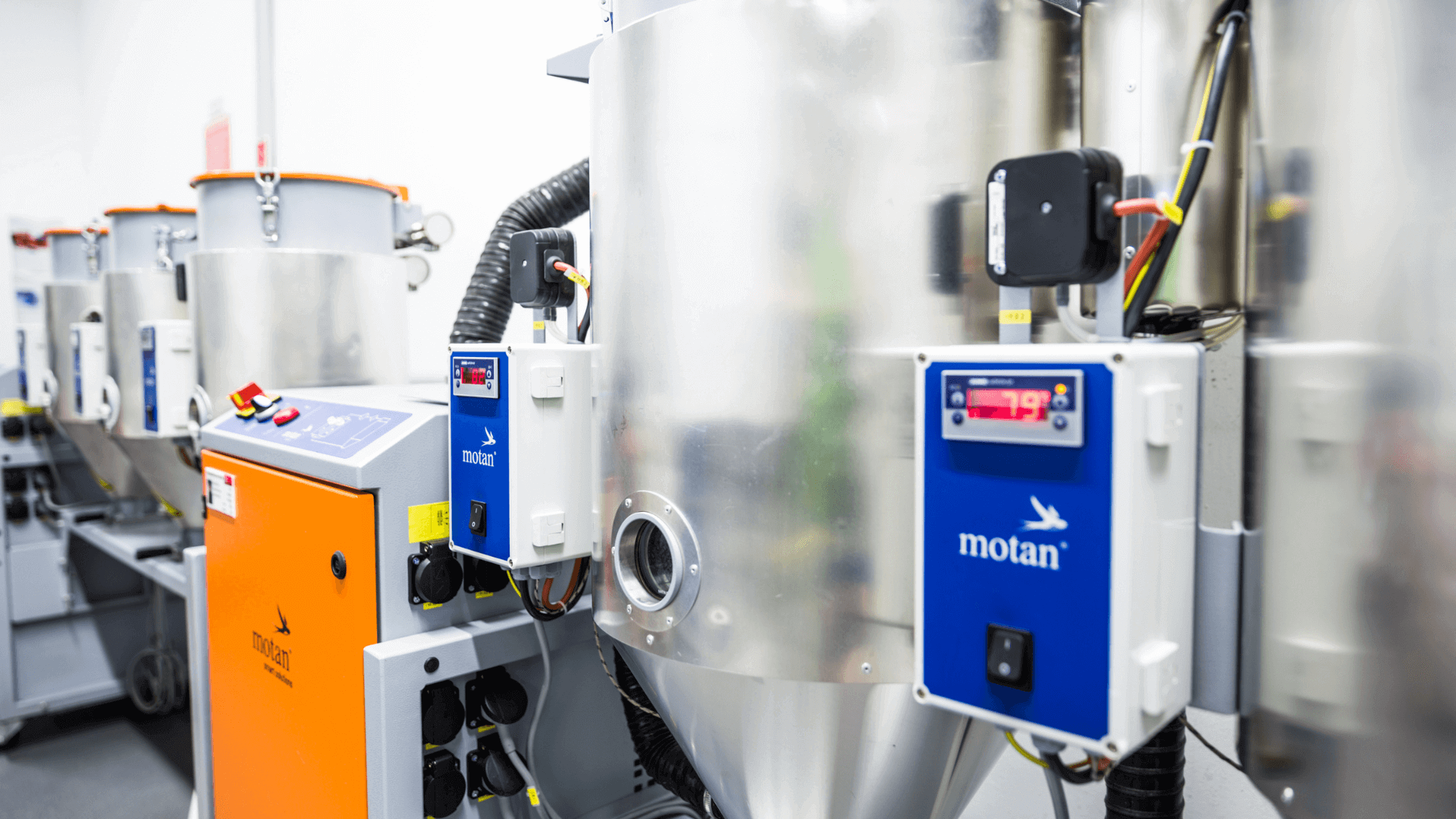

Our portfolio of application and mold technology services is diverse. We support you in the development of molded parts and injection molds, the integration of new processes through to process engineering implementation in the entire field of thermoplastic and thermoset processing. We also work for you worldwide and help you to optimize existing processes. Our practice-oriented specialists and well-equipped technical center are at your disposal for this purpose.

Sampling & test samples

In our technical center, in addition to the usual standard test specimens, we also offer sampling of new or problematic tools under near-series conditions – as part of initial, functional or follow-up sampling. The aim of sampling and the production of test specimens is to uncover weak points and optimization potential through a systematic approach in order to generate a tool suitable for series production. We process thermoplastics and thermosets.

Our machinery includes

- 9 injection molding machines including state-of-the-art peripherals in the clamping force range up to 240t

- Conventional thermoplastic injection molding machines

- Various foaming technologies

- In Mould Coating

- Thermoset press

- Elastomer machine

The most commonly used screw range is between 15 and 45 millimetres, but individual requirements can also be met. Thanks to decades of development work, we can offer special solutions for many issues and also have the corresponding hardware in-house. As we have developed or co-developed many processes ourselves, we have mastered them, but also know their limitations. Another advantage is our close proximity to our analytical laboratory. This means that, if required, we can directly evaluate your components or test specimens and the sampling results analytically under one roof. The quality of the components is paramount and the decisive question is: “Can the required component quality be achieved with the help of process engineering changes, or is it not possible to achieve the required quality? We take care of this for you!

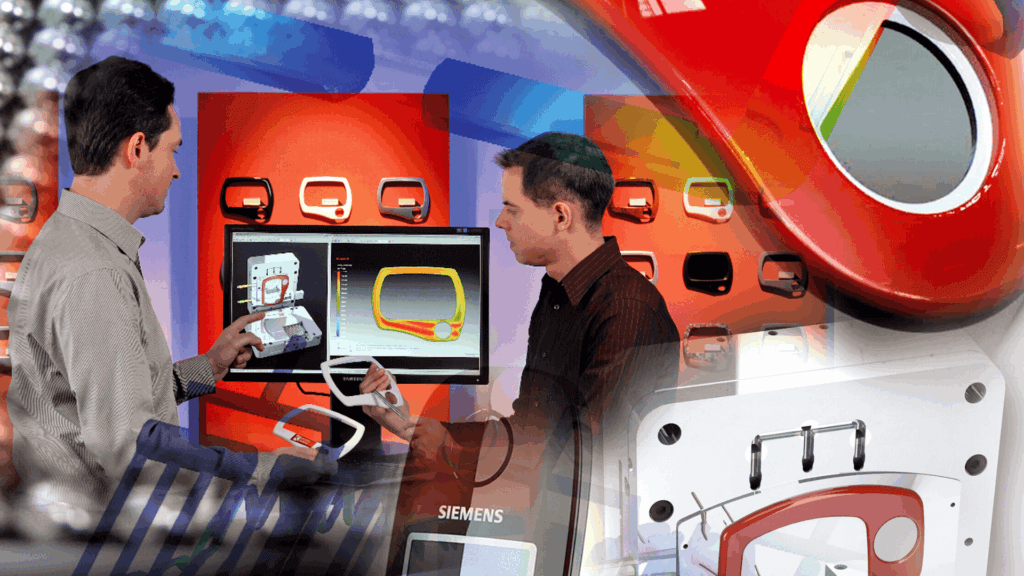

Simulation

We support you in the optimization of moulded part and tool design. Computational design using software support (CAE). We can support you in your concerns with very short lead times and many years of experience in simulation and develop an individual solution! Achieve your goals in molded part and tool design! Injection molding simulation is used before the actual article or tool implementation in order to avoid errors in the design phase and thus shorten project times.

Our main topics

- Optimization of moulded part and tool design through targeted interpretation of results

- Rheology (filling or filling simulation)

- Thermics

- Shrinkage and warpage

- Special processes (e.g. multi-component technology)

- Thermoplastic and thermoset simulation

- Mechanical tool and article analysis using FEM calculation

- Evaluation of customer simulations

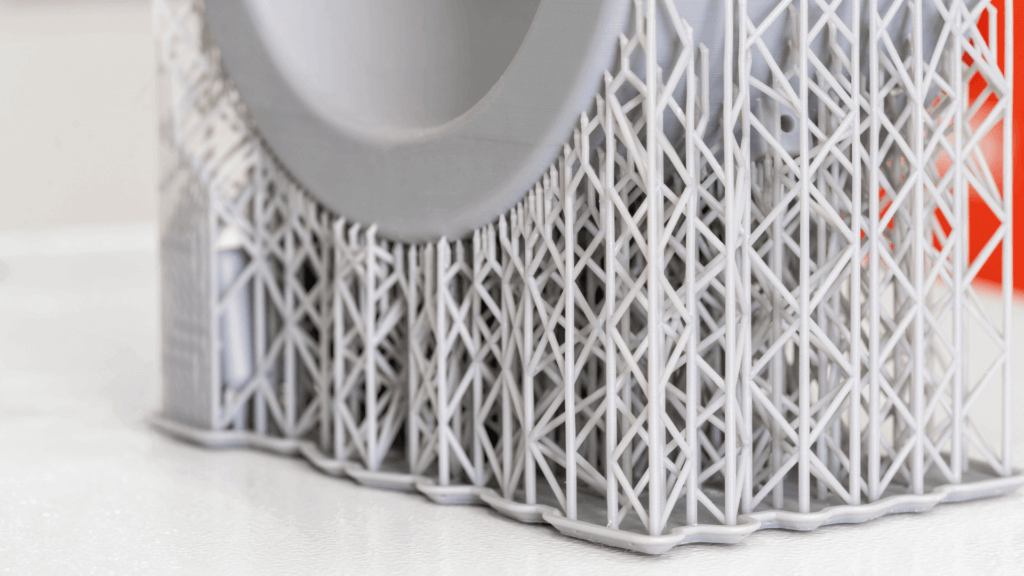

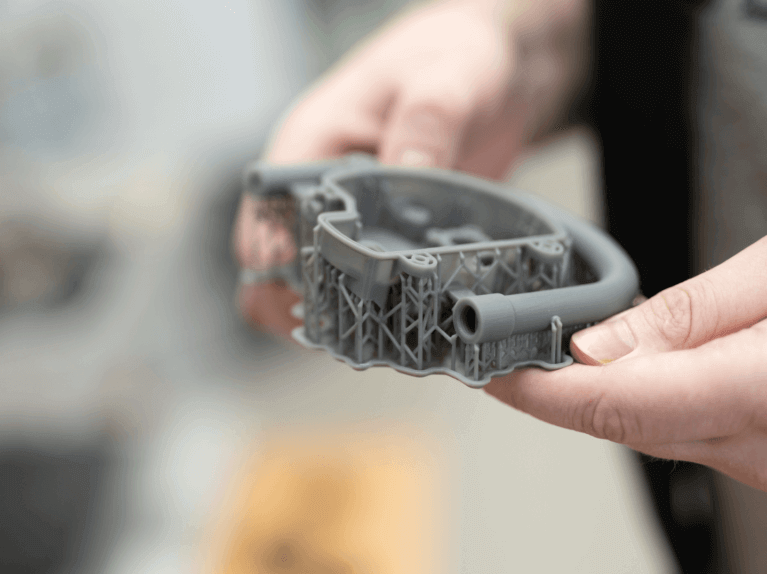

Additive manufacturing

We have an innovation center for additive manufacturing technologies (IAF) at our institute in Lüdenscheid.

Generative. Additive. Pioneering.

In our innovation center for additive manufacturing technologies, we can print components for you using various processes.

We offer you

- FFF (up to 300°C mass temperature and continuous fiber possible)

- FDM (ABS or PEEK)

- SLA (various photopolymers with a wide range of properties)

- SLS (PA 11, 12 and TPE)

- Filament production of plastics with up to 400°C mass temperature and 4mm diameter

- Support for 3D printing in process selection and component design

- Rapid tooling (production of injection molded components from printed plastic inserts)

- Industrial 3D printing

- Long-term behavior of additive components

- Production of prototypes and components in small series

Solutions start with

the right conversation

Jede Funktion braucht das richtige Fundament

Whether it’s a series production start, process optimization or a special solution – we think our way into your application and develop the right implementation together. Get in touch – we look forward to hearing about your project.

Dipl.-Ing. Andreas Kuerten

Head of the “Application Technology” division

+49 2351 1064-101 a.kuerten@kimw.de

Dipl.-Ing. Christian Kuerten

Head of the “Application Technology” division

+49 2351 1064-102 c.kuerten@kimw.deEvents

-

19.02.2026

Einstieg in die Spritzgießtechnik

Lüdenscheid Seminar -

25.02.2026

Einstieg in die Duroplastverarbeitung

Lüdenscheid Seminar -

25.02.2026

IMCcon 2026

Lüdenscheid Fachtagungen/Fokustage/Foren -

03.03.2026

Agenda Fokusgruppe (FG) “Kunststoffoptik”

Online Fachtagungen/Fokustage/Foren -

03.03.2026

Spritzgießen für Kaufleute

Lüdenscheid Seminar