research focus –

Idea meets substance

Research Developing technologies for your success

Our research activities focus specifically on practical issues and their solution-oriented implementation. The emphasis is on innovations that are technically convincing and can be directly transferred to industrial applications. Through interdisciplinary cooperation and the pooling of expertise from various specialist areas, we create the basis for application-oriented results. A strong network of industry partners, research facilities, and institutions supports our work, ensuring short communication channels, rapid knowledge transfer, and sustainable solutions. Our research does not take place in an ivory tower, but in the heart of practical application, with a clear goal: to create innovations that work and deliver real added value.

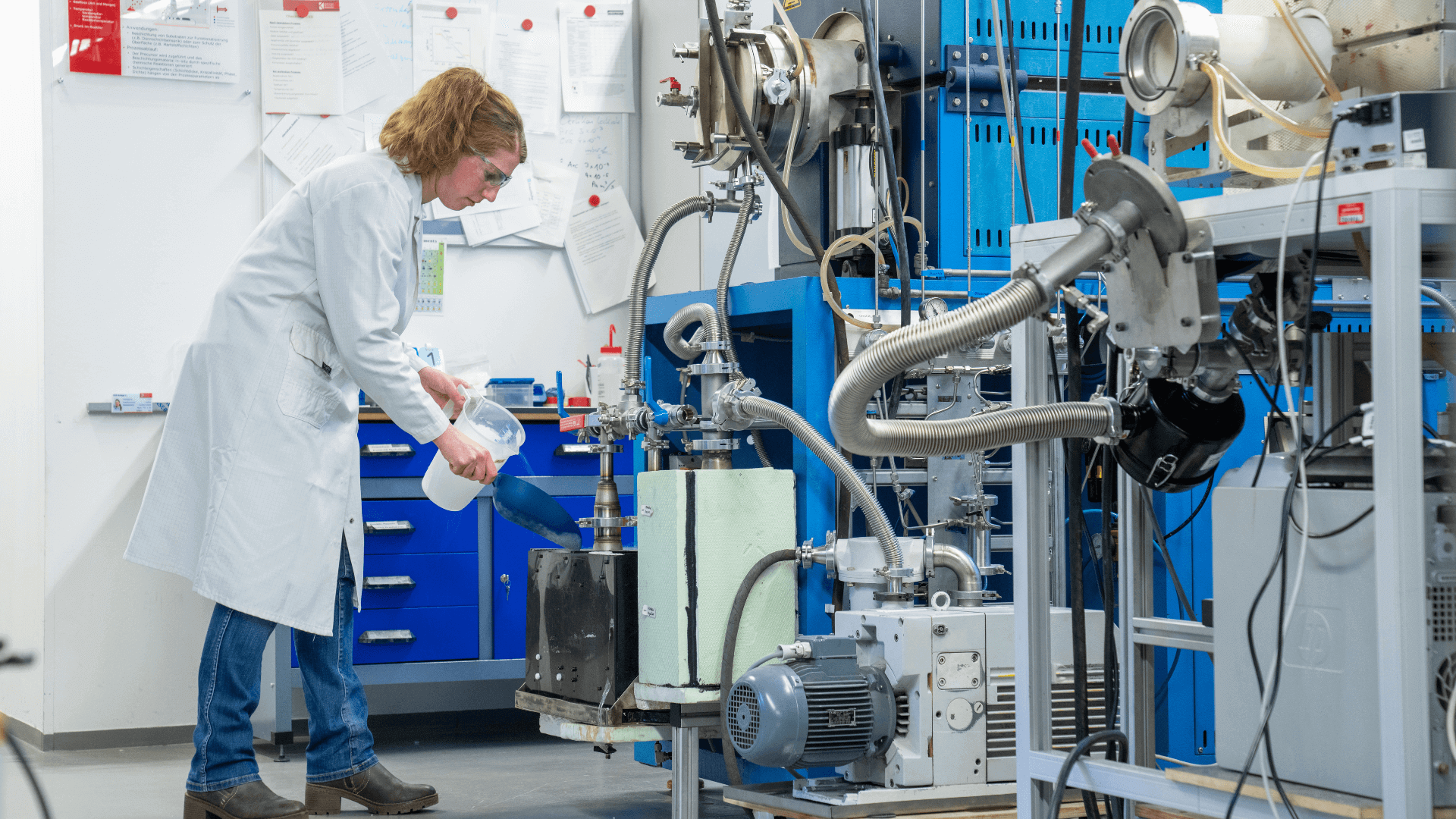

Coating technology

Surface engineering is an exciting key technology for high-performance components. Thin layers open up a wide range of possibilities for significantly exceeding the properties of solid materials. Depending on the coating system, it is possible to achieve extreme wear resistance up to diamond hardness, low-friction surfaces such as graphite, chemical resistance comparable to Teflon, or high temperature resistance such as ceramics. In combination with carefully selected base materials, innovative composite materials are created that have become indispensable in modern manufacturing processes.

- Process development for CVD coating processes

- Application-oriented selection of surfaces and coating technologies

- Low-temperature CVD coating technologies for tools and components

- Nanostructuring of tool surfaces for demolding and counterfeit protection

- Coating characterization using various methods

- Operating test benches for corrosion, wear, tribology, indexed heat transfer measurements, and more

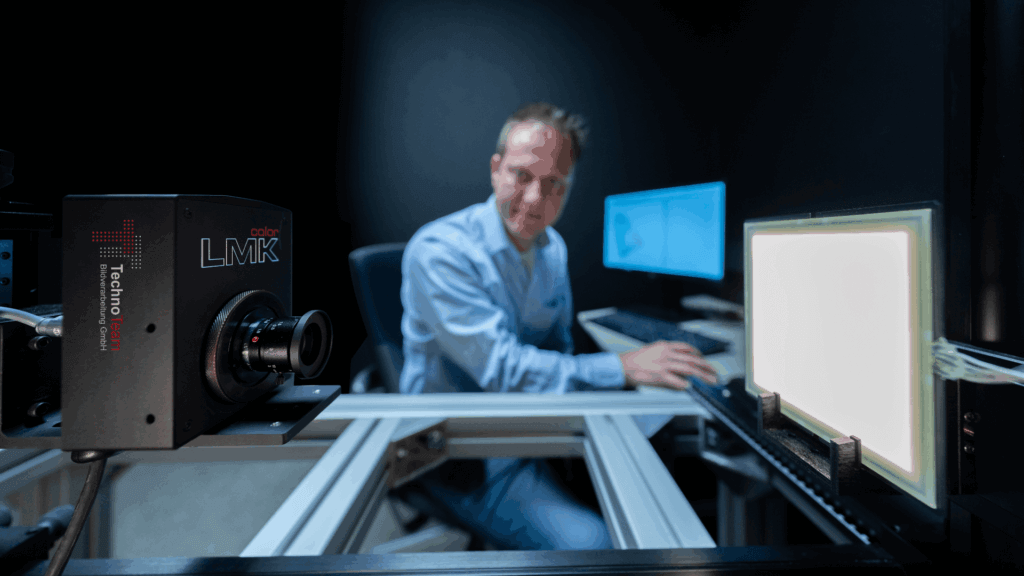

Lighting technology

Lighting technology has undergone rapid development in recent years. In addition to a wide range of technological developments in the field of light sources, such as LED and OLED technology, the functional requirements for plastic components and assemblies for lighting applications have also risen steadily. The assemblies are responsible in particular for targeted light guidance, light control, and light output, and have a significant influence on quality. A wide range of research and services is available to developers and users from a wide range of industries, e.g.:

- Selection and evaluation of tool concepts for the manufacture of optical plastic components

- Manufacture of precise optical components by injection molding and injection transfer molding

- Material research and selection

- Concept and feasibility development for symbol and ambient lighting

- Development and manufacture of prototypes and design samples

- Measurement of absolute luminance

- Measurement of light color

- Determination of illumination homogeneity

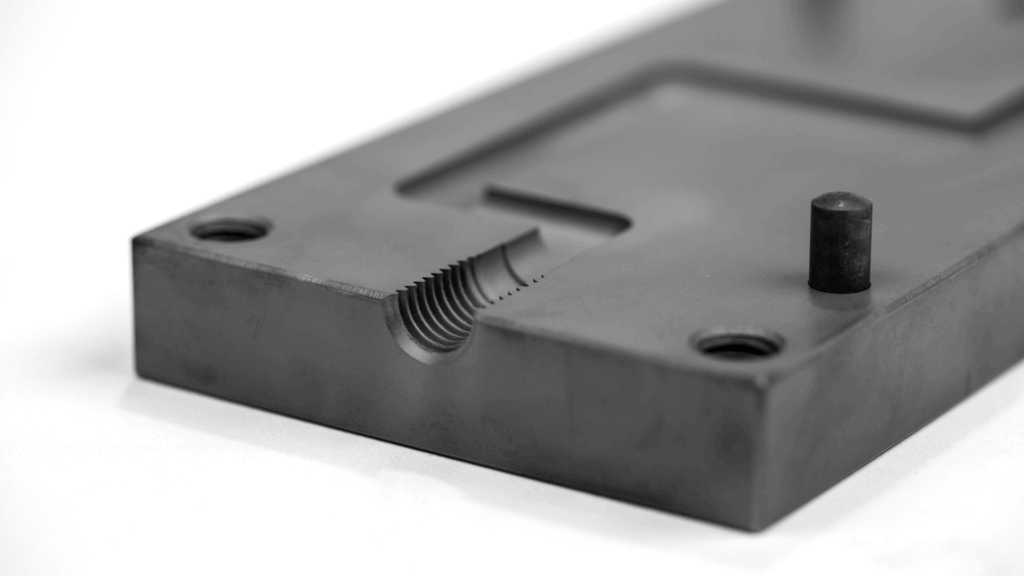

Tool &

Process Technology

Tools are at the heart of many manufacturing processes. They are subject to constant change in line with increasing quality and cost-efficiency requirements. A key focus of our work is the development and refinement of tools for plastics processing with a view to increasing productivity and component quality and reducing the energy required for processes.

Focus areas for tools

- Design and testing of innovative heating and temperature control systems

- Development of special tool components

- Research into new possibilities for manufacturing tool components

- Simulative tool design

Process technologies have a significant influence on the cost-effectiveness, quality, and CO2 footprint of products. We research and develop manufacturing processes for plastics processing in response to changing requirements, such as in the areas of lightweight construction or integrative production processes.

Focus areas of process technologies

- New and further development of injection molding processes and finishing processes

- Back molding of decorative and functional inserts

- Simulative process design

- Resource-efficient production

- Condition monitoring

material development

In all areas where safety aspects such as fire protection or hygiene play a role, the plastic components used there must meet the highest standards. This

is particularly the case for electronic devices, in the textile industry, in construction, in the automotive industry, for housings and devices, and for surfaces in the medical sector.

In order to equip plastic components and surfaces with the appropriate functionalities, we focus on

- the development of additives

- the processes used to integrate the functionalities

- the compounding of modified fillers

- the development of biocidal nanoparticles for integration into plastics, paints, and coatings

- the analysis of functionalities

- material research and selection

Research needs

exchange

Schnittstelle für Forschung, Technik und Transfer

Would you like to learn more about our research focus areas or do you have a specific question from your field of work? Ask us—we are here to assist you with our expertise and experience.

Dr.-Ing. Angelo Librizzi

Process and tooling / lighting technology

+49 2351 1064-134 librizzi@kimw.de

Events

-

03.03.2026

Agenda Fokusgruppe (FG) “Kunststoffoptik”

Online Fachtagungen/Fokustage/Foren -

03.03.2026

Spritzgießen für Kaufleute

Lüdenscheid Seminar -

04.03.2026

PFAScon 2026

Lüdenscheid Fachtagungen/Fokustage/Foren -

05.03.2026

Basiswissen der Form- und Lagetoleranzen

Lüdenscheid Seminar -

05.03.2026

Kunststoffgerechte Formteilauslegung

Lüdenscheid Seminar