Research infrastructure - when industry

and innovation come together

Research Application-oriented research, targeted further development

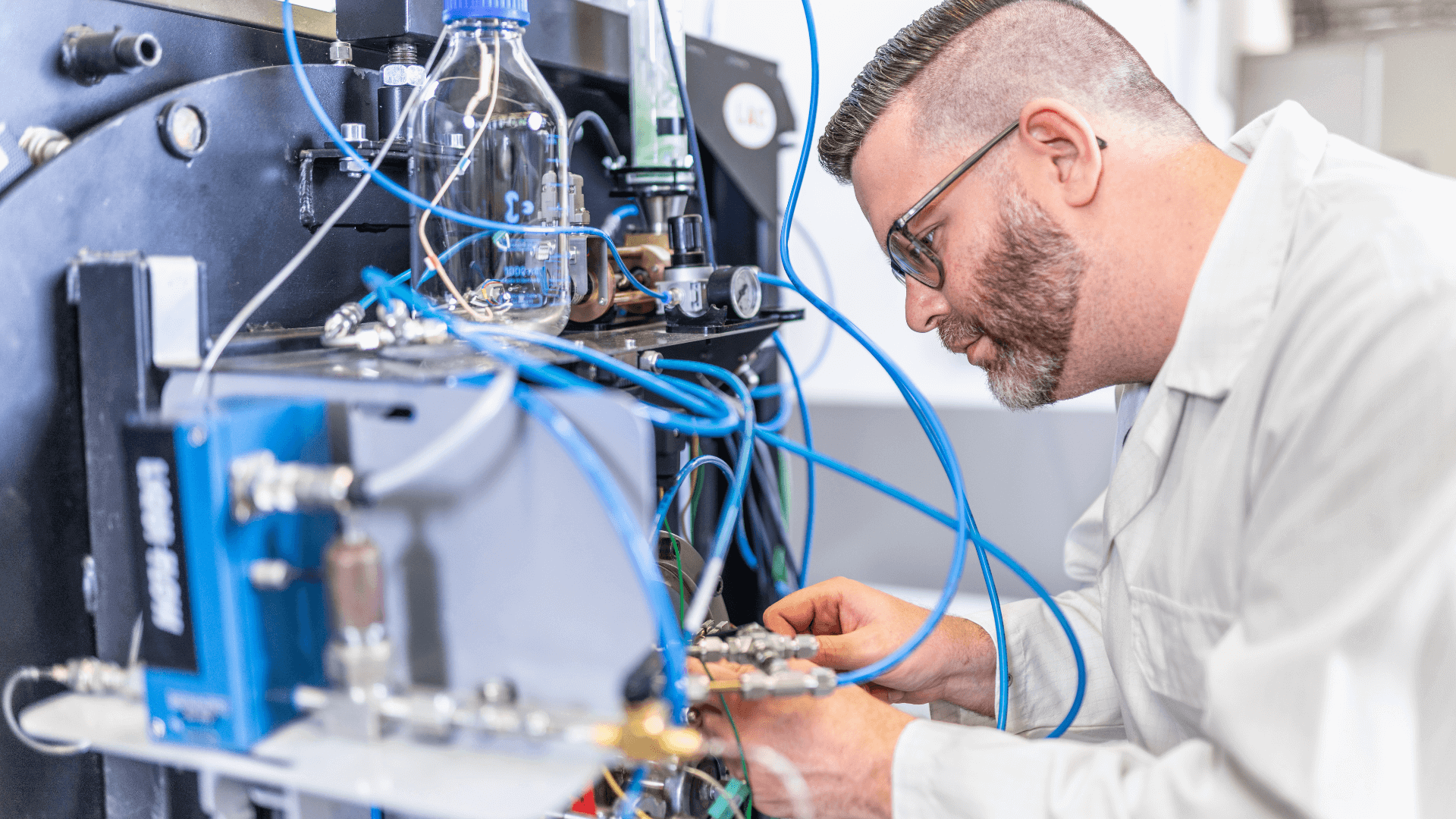

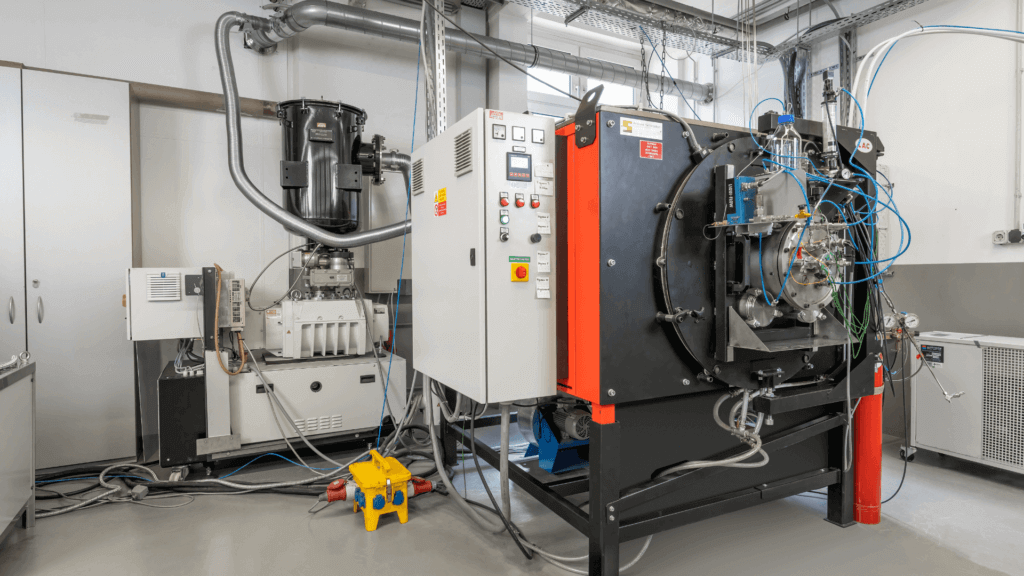

Our research infrastructure is geared towards creating solutions for real challenges. In close cooperation with industrial partners and research institutions, we analyze materials, surfaces and processes down to the last detail – using state-of-the-art technology and interdisciplinary expertise. The focus is always on practical feasibility: from the initial idea to analysis and concrete process optimization, we offer an environment in which research creates real added value.

Analytics -

Making visible what others cannot see

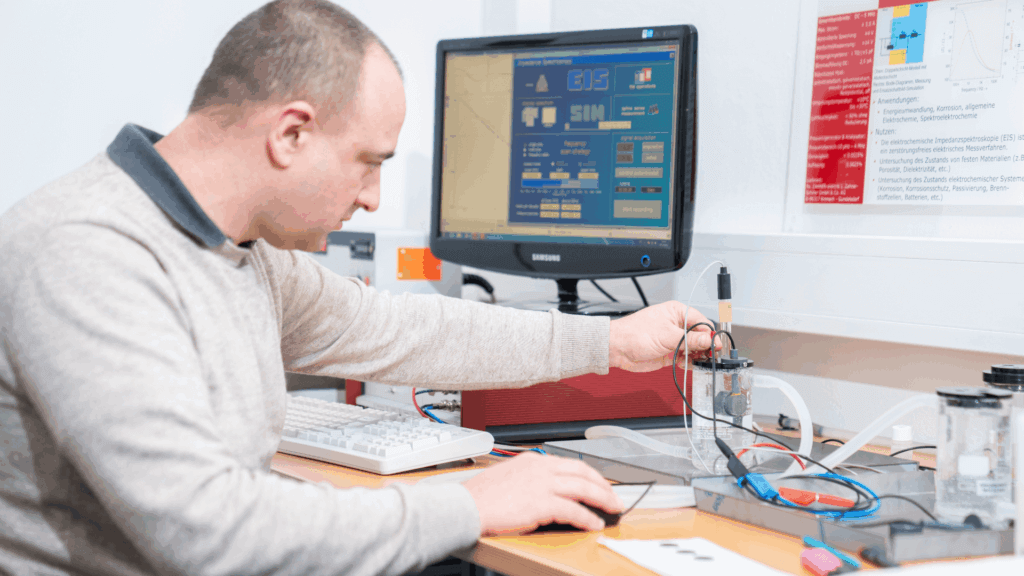

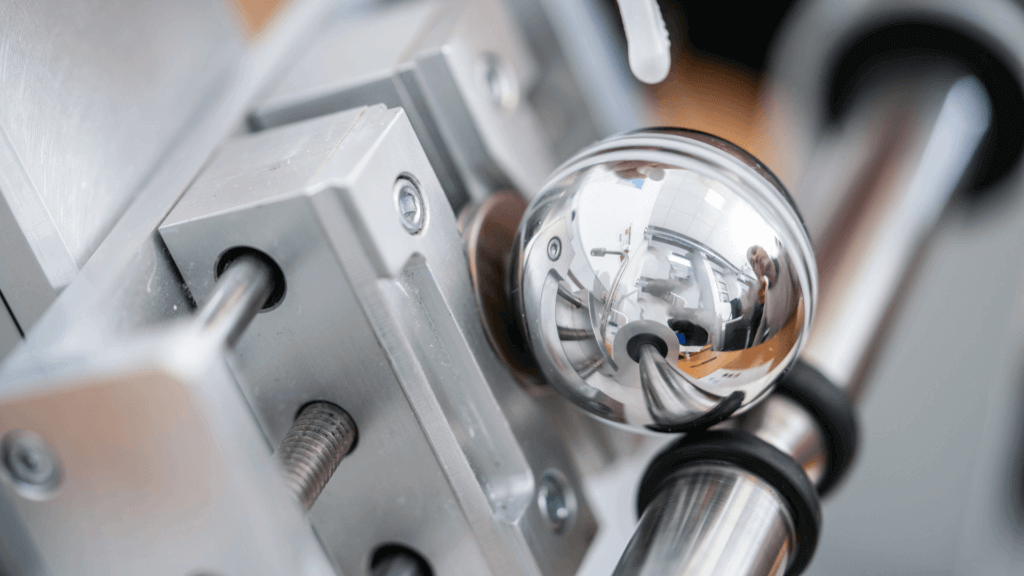

Thanks to the available analysis equipment, we are able to examine new developments and optimizations in the field of coating and process technology efficiently and promptly with regard to physical and chemical properties. The topography, roughness, abrasion resistance and hardness of surfaces can be analyzed and the layer structure, layer thickness and layer composition as well as porosity and electrochemical behaviour can be investigated.

The following analysis devices are available

- Scanning electron microscope (SEM) with energy dispersive X-ray spectroscopy (EDX)

- Micro-/ Nano-mechanical measuring device/ Micro-Combi-Tester (MCT)

- X-ray fluorescence analyzer (XRF)

- Electrochemical impedance spectroscopy (EIS)

- Digital microscope

- Calotte grinding device

- Residual gas analyzer (RGA)

- Thermal diffusivity test bench

- Rockwell indentation test

Operational test benches -

For real operating conditions

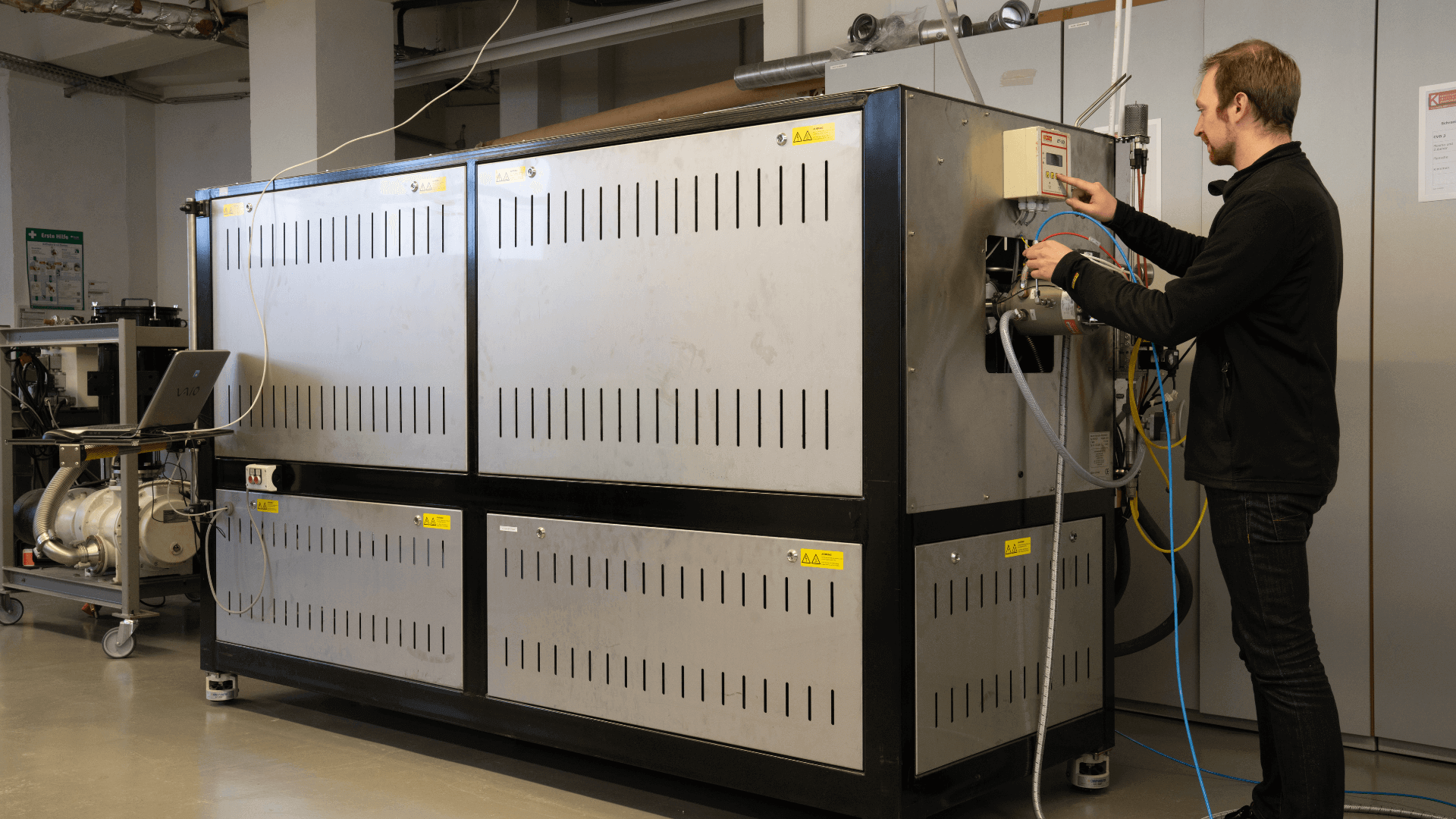

Mapping processes as realistically as possible in order to be able to test new developments and optimizations in a process-related environment is the basis of our application-oriented research.

In the course of this, the following operational test benches were set up

- Demoulding force measurement / adhesive force analysis

- Emission measurement

- Wear measurement in the injection mould

- Corrosion in the injection moulding process

- Friction test bench, tribology measurements

- Indexed abrasion measurement

- Indexed thermal conductivity measurement

Access to research,

opens the doors

Your connection to state-of-the-art infrastructure and practical expertise

Would you like to use our research infrastructure for your project or do you have questions about technical equipment and cooperation opportunities? We will advise you personally and find out together how you can make targeted use of our laboratories, systems and test benches.

Whether you have an individual inquiry or a partnership project – we look forward to exchanging ideas with you.

Leistungsüberblick

Events

-

05.02.2026

Spritzgießen Thermoplaste – die Basics

Lüdenscheid Seminar -

10.02.2026

ECO.MATERIALScon

Lüdenscheid, Online Fachtagungen/Fokustage/Foren -

11.02.2026

Formteilfehler an thermoplastischen Spritzgussteilen

Lüdenscheid Seminar -

11.02.2026

Lesen von Simulationsergebnissen

Lüdenscheid Seminar -

12.02.2026

Ausbildungsprogramm Ingenieurnahe Qualifikation: Produktentwicklung

Lüdenscheid Weiterbildung